| 原産地: | 中国(本土) | 銘柄: | yiboエポキシ油圧ゲル成形機 | モデル番号: | APG898エポキシ油圧ゲル成形機 | モデル: | APG898エポキシ油圧ゲル成形機 | クランププレート: | 1000*1000ミリメートル | 上下コア引っ張っストローク: | 800ミリメートル、500ミリメートル | 金型クランプ力: | 220KN | 金型クランプ速度: | 3.2メートル/分 | マックス金型クランプ距離: | 1500ミリメートル | 最小金型クランプ距離: | 250ミリメートル | 電源の油圧駅: | 7.5kw | 加熱パワー: | 16kw | incliation角度の完全なマシン: | 6500キログラム | 段階: | 単一 | コイルの構造: | 円環形状 | コイル数: | 単巻変圧器 | 使用法: | 現在 |

包装

| 包装: | エポキシゲル油圧成形機の使用膜のプラスチック保護フィルムと他の部品の使用安全出荷用の木製ケース。 と40オープントップコンテナ、 apgマシン、 モデルなし。: yiboapg- 898重量: 8000キロ油圧でシステム・アクセサリー: 千キロ電気制御キャビネット: 500kgマシンフレーム: 4350kg上部コア- 引っ張る、 デバイス・エジェクタアクセサリー: 300キロ真空攪拌混合装置: 450kg真空攪拌混合装置、 噴車両: 1400キロ |

| PLC control Emdedded pole,CT,PT,Wall Bushing ,Insulator, Epoxy Hydraulic Gel Injection Machine APG898 |

APG machine is large-sized equipment,mould as large as 1000*100mm,has large upper and lower core pulling distance.

It is appliance for large-sized products such as transformer,large insulating cylinder,contact cover,bending plate,insulating housing,disc insulator,etc.

The composition of the APG Claming Machine:The main machine+Mixing device(three sets)+ Stirring rack+Hydraulic Oil Pump+ Power distribution cabinet.

| Main Technical Parameters: |

| Serial No. | Item | Technical Parameters |

| 1 | Clamping Plate | 1000*1000mm |

| 2 | Upper and lower core-pulling stroke | 800mm,500mm |

| 3 | Mould clamping force | 220KN |

| 4 | Mould clamping speed | 3.2m/min |

| 5 | Max mould clamping distance | 1500mm |

| 6 | Min mould clamping distance | 250mm |

| 7 | Power of hydraulic station | 7.5kw |

| 8 | Heating power | 16kw |

| 9 | Incliation angle of complete machine | Vertical 0-5 degree,Horizontal 0-5 degree |

| 10 | Weight of complete machine | 6500KG |

| 11 | Mould-filling weight | 6 tone |

| 12 | Outline Dimension | 4900(L)*1630(W)*4200(H)mm |

| Automatic Pressure Gelation Process: |

APG process (Automatic Pressure Gelation Process referred to as the APG process) was first filed a patent on June 19, 1969 by Ciba-Geigy, Switzerland. In China, with the development of pressure gelation equipment and its continuous improvement under the Coal Research Institute, as well as the gap between local epoxy resin specialized for pressure gel and imported material increasingly narrow, pressure gelation process in the electrical insulation industry has also been expanded, and has played an irreplaceable role. Pressure gelation technology is now successfully used in the production of high quality enclosed pole, cross-fluorinated sulfur load switch housing, transformers and other products.

Pressure gel process to produce the insulators as outlined below:

1.material pretreatment

A certain percentage of epoxy resin speical for pressure gel, curing agent, fillers, colorants join the mixing tank. Stir 1 to 2 hours to mix material evenly and no bubbles in the sealed pot under a vacuum state (absolute pressure is less than 500Pa).

2.injecting, forming

Pretreated epoxy resin mixture is injected into the APG mold preheating to 140deg with the help of compressed air or pressurized pump. The mixture is released from the mold after thermal gel forming and get semi-finished products.

APG mold should be set aside suitable gap in a specific parting line surface in order to discharge the air from the mold in the process of injecting material. After the gel injecting into the mold, the epoxy resin due to rapid heating fill into the small gap, leaving the mold in a sealed state, so the material within the mold under pressure gradually gel to get a close texture product. In order to make the mold parting line surface leaving some gap not only able to exhaust but also reliable seal, which require higher accuracy of the mold, especially for some of the complex structure of the insulators, the mold is with much higher accuracy requirements. In short, Pressure gel mold is equipped with a high technical content.

3.curing

After injection, the products are transferred to the oven, and the finished products get dense and low internal stress after slow cooling under constant temperature of 140deg 10 hours.

| Reasons to choose us: |

| Quality assurance: |

1.The biggest&only manufacturer at the same time do the APG Clamping Machine and APG Mould in china so that make the machine with the mold better coordination which ensure that product qualification.

2. The only company have product testing room in china,if necessary you can stay in our factory test output products(through the dielectric strength testing--the impact testing--the bending testing--partial discharge testing) until being qualified&higher quality and ready to shipment.

3.CE,ISO,SGS certificate and standards,owns many patents and independent intellectual property rights.

4.We can customize machine according to customer's needs.

| Excellent aftersales services: |

1. Have 23 year's experience of electric products production technology engineers to your company provide free technology training and help customers make the qualified products.

2. Have rich experience engineer to be responsible for new equipment storting to installation debugging and training.

| Competitive ability of production: |

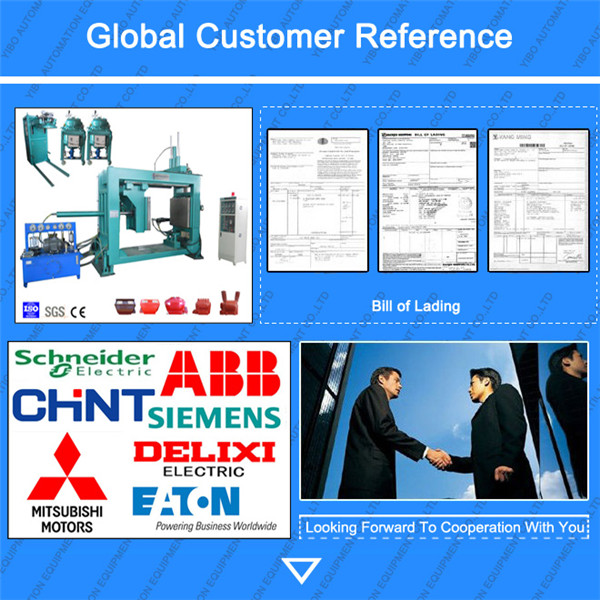

Well equipped with complete facilities and more than 200 skilled workers and operates round the clock on three shifts,so we can keep the orders completed punctually!

| updat the details: |

1. Specially designed for transformer of thin film degassing and cycle heating system mixing device, greatly improving the uniformity of mixing and pumping vacuum material.

2.Combination of equipment, moulds, as well as under the engineers constantly summarize and improve the production equipment has superior performance,high efficiency energy saving etc.

3.By APG pressure gel molding process, greatly improving the production efficiency, increased the product surface bright and clean degree, reduce the mold cost, reduces the labor costs of inputs.

4.One-stop services for electric factory,we are manufacturer APG Clamping Machine,APG Mould,Oven for APG Processing,Winding Machine for CT&PT,Foil Winding Machine for Transformer,Laser Marking Machine can marking all kinds of materials,like epoxy resin.

| Manufacturer's Price: |

Factory direct sale,most competitive price.

| Warranty: |

12 Months and lifelong maintenance.

YIBO factory can provide epoxy casting, APG technology, mold epoxy resin molding machine,APG Molds,Toroidal Widing Machine,Transformer Foil Winding Machine,Laser Marking Machine all in one service for users

APG series has the following several types: |

Epoxy resin clamping machine APG1210 type, the heating plate 1000 x 1200mm.

Epoxy resin clamping machine APG898 type, the heating plate 1000x 1000mm,

Epoxy resin clamping machine APG888 type heating plate 800 x 800mm,

Epoxy resin clamping machine APG865 type heating plate 800 x 600mm,

Epoxy resin clamping machine APG885 type heating plate 800 x 800mm,

Epoxy resin molding machine factory after years of working experience in actual combat summary design, epoxy resin pressure forming machine for customer verification and improvement of the factory, has formed a complete series, epoxy resin pressure molding machine adopts PLC control, (also can be man-machine interface operation) is more humanized, compared with the domestic similar products have the characteristics of the beyond.