| 原産地: | 中国(本土) | 銘柄: | elaiter | モデル番号: | y型、 xタイプ | y型: | 125y、 160y、 250y、 350y、 400y、 450y、 500y、 700y。 | xタイプ: | 100x、 125x、 160x、 250倍、 350x、 400x、 450x、 470x、 500分、 550x、 700x。 | 最大。 動作温度。( 度c): | 1400 | モース硬度( スケール): | ≥7 | アプリケーション: | として使用しタワーのパッキング |

包装

| 包装: | 木枠、 パレットする段ボール箱。 |

Ceramic packing structured packing is applied to the drying tower, absorbing tower, cooling tower, desulphurization towers, rectifying tower, washing tower, coal gas scrubbing tower, coking scrubbing benzene tower, scrubbing NH3 tower, ammonia washing tower,naphthalene washing tower, fertilizer saturation-heat water column and scrubbing tower, fertilizer heat gas saturation tower and regenerative tower.

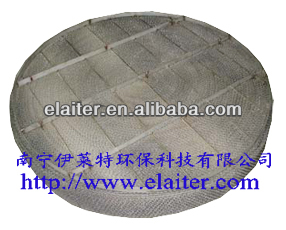

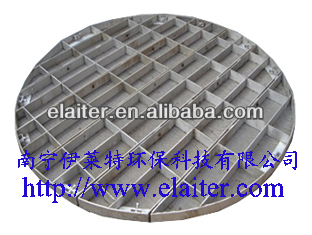

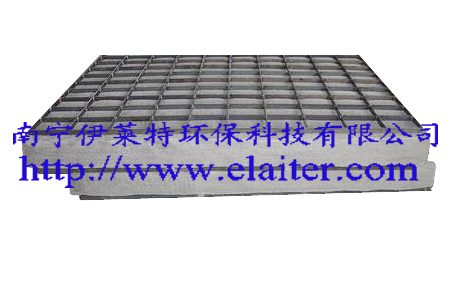

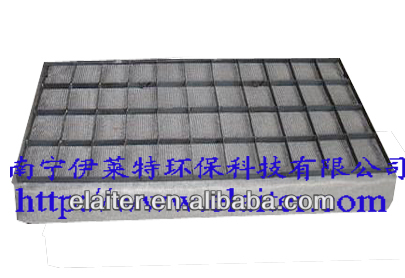

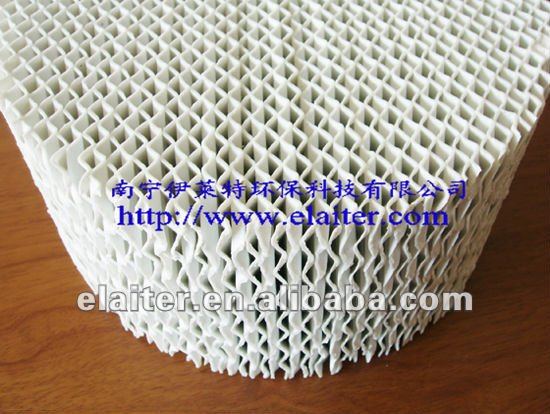

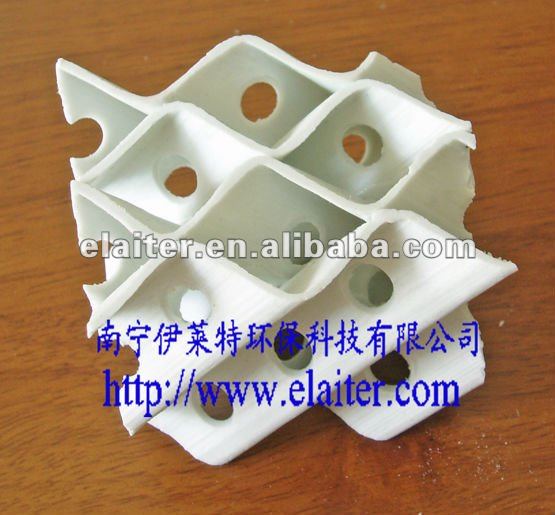

Ceramic packing structured packing is composed of many packing units with the same geometric shapes. Each packing unit consists of parallel superposed corrugated sheets. Ceramic structured packing has high efficiency, low pressure drop, high capacity, small liquid holdup; scale effect is not obvious, large flexibility, corrosion resistance, heat resistance etc. It can widely used in the coal gas scrubbing tower, coking scrubbing benzene tower, scrubbing NH3 tower, fertilizer saturation heat water column and scrubbing tower, etc.

1. Mainly application of ceramic packing structured packing:

(1). Sulfuric and acid plants.

(2). Regenerative thermal oxidizers.

(3). Chlorine cooling and drying towers.

(4). Bromine and hydrochloric acid plants.

(5). Liquid organic waste disposal coolers and scrubbers.

(6). Natural gas treating and dehydration units.

(7). Purification of aqueous organic acids.

2. Chemical composition of ceramic packing structured packing:

SiO2 | Fe2O3 | CaO | Al2O3 | MgO | Other |

≥72% | ≤0.5% | ≤1.0% | ≥23% | ≤1.0% | 2% |

3. Physical property of ceramic packing structured packing:

Index | Value |

Specific gravity (g/cm3) | 2.5 |

Water absorption (wt%) | ≤0.5 |

Acid resistance (wt%) | ≥99.5 |

Loss in burn (wt%) | ≤5.0 |

Max. operating Temp.(Degree C) | 1400 |

Crush strength (Mpa) | ≥130 |

Mohs hardness (Scale) | ≥7 |

4. Technical data of ceramic packing structured packing:

Type | Specific surface area (m2/m3) | Bulk density (kg/m3) | Void ratio ( %) | Obliquity | Pressure Drop (mmHg/m) | Theoretical Plate(1/m) | Hydraulic Diameter (mm) | Liquid Load (m3/m2.h) | The biggest F factor (m/s(kg/m3)0.5) |

125Y | 125 | 320 | 90 | 45° | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

160Y | 160 | 370 | 85 | 45° | 2 | 2 | 15 | 0.2-100 | 2.8 |

250Y | 250 | 420 | 80 | 45° | 2.0 | 2.5 | 12 | 0.2-100 | 2.6 |

350Y | 350 | 470 | 78 | 45° | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

400Y | 400 | 500 | 75 | 45° | 3.0 | 3.0 | 8 | 0.2-100 | 2.0 |

450Y | 450 | 520 | 72 | 45° | 4.0 | 4 | 7 | 0.2-100 | 1.8 |

500Y | 500 | 620 | 74 | 45° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

700Y | 700 | 650 | 72 | 45° | 6.0 | 7 | 5 | 0.15-100 | 1.3 |

100X | 100 | 280 | 92 | 30° | 1.5 | 1 | 30 | 0.2-100 | 3.5 |

125X | 125 | 300 | 90 | 30° | 1.8 | 1.5 | 28 | 0.2-100 | 3.2 |

160X | 160 | 350 | 85 | 30° | 2.0 | 1.8 | 15 | 0.2-100 | 3.0 |

250X | 250 | 380 | 80 | 30° | 2.5 | 2.3 | 12 | 0.2-100 | 2.8 |

350X | 350 | 450 | 78 | 30° | 3.0 | 2.5 | 10 | 0.2-100 | 2.6 |

400X | 400 | 480 | 75 | 30° | 4.0 | 2.8 | 8 | 0.2-100 | 2.2 |

450X | 450 | 500 | 72 | 30° | 4.5 | 3-4 | 7 | 0.2-100 | 2.0 |

470X | 470 | 440 | 75 | 30° | 5 | 5 | 7 | 0.2-100 | 1.8 |

500X | 500 | 620 | 74 | 30° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

550X | 550 | 620 | 74 | 30° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

700X | 700 | 650 | 72 | 30° | 6.0 | 7 | 5 | 0.15-100 | 1.3 |

Tips: X = 30° (Corrugated Angle of Inclination), Y = 45° (Corrugated Angle of Inclination). The number front of X/Y means the packing’s specific surface area (m2/m3).