| 原産地: | 中国(本土) | 銘柄: | elaiter | モデル番号: | xタイプ、 y型 | y型: | 125y、 160y、 250y、 350y、 400y、 450y、 500y、 700y。 | xタイプ: | 100x、 125x、 160x、 250倍、 350x、 400x、 450x、 470x、 500分、 550x、 700x。 | 最大。 動作温度。( 度c): | 1400 | モース硬度( スケール): | ≥7 | アプリケーション: | として使用しタワーのパッキング |

包装

| 包装: | 木枠、 パレットする段ボール箱、 他の梱包が、 あなたのリクエストを承り。 |

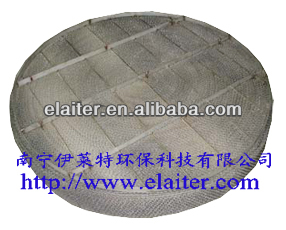

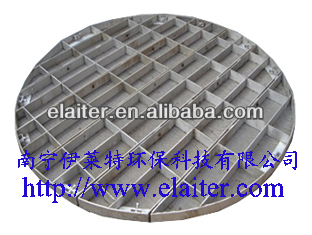

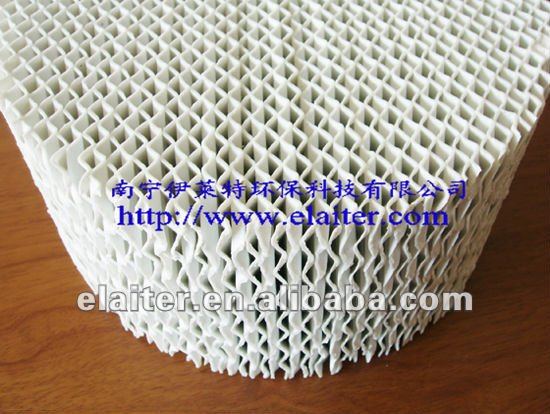

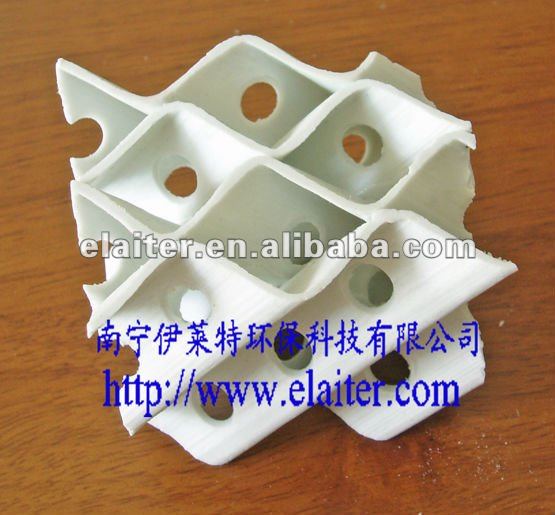

Ceramic structured packing is applied to the drying tower, absorbing tower, cooling tower, desulphurization towers, rectifying tower, washing tower, coal gas scrubbing tower, coking scrubbing benzene tower, scrubbing NH3 tower, ammonia washing tower,naphthalene washing tower, fertilizer saturation-heat water column and scrubbing tower, fertilizer heat gas saturation tower and regenerative tower.

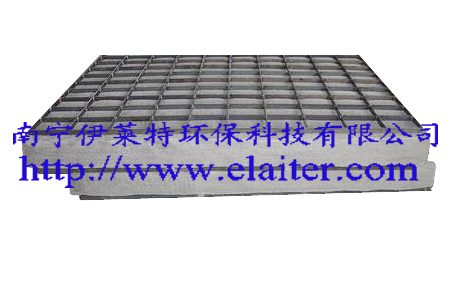

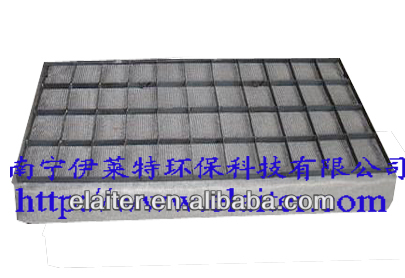

Ceramic structured packing is constructed of corrugated sheets of ceramic. The angle of inclination of the corrugations of adjacent sheets is reversed with respect to the vertical column axis, forming mixing cells at every point wher the corrugation intersect. This promotes intimate mixing and radial distribution of the liquid and gas streams. Each subsequent element is rotated about the column axis so that the sheets of one element are opposed to the sheets of the elements above and below. In passing through each element, gas and liquid are thoroughly mixed in the direction parallel to the plane of the sheets. By rotating subsequent elements, excellent mixing and spreading, both side to side and front to back are obtained over the entire cross section of the tower. The flow characteristics developed by the structured geometrical arrangement creates high effective surface area resulting in good efficiency as compared to other mass transfer devices.

1. Features of ceramic structured packing:

(1). High liquid & vapor loading, Column diameter could be designed smaller for new equipment and capacity could be increased dramatically for existing column revamp.

(2). High resistance to nearly all mineral and organic acids and derivatives, partly resistant to alkalis.

(3). High mass-transfer efficiency, much higher specific surface area than random packing.

(4). Low pressure drop, considerable energy savings.

(5). Wide turndown ratio, Easy to scale up.

(6). Suitable for all sizes of column.

2. Chemical composition of ceramic structured packing:

SiO2 | Fe2O3 | CaO | Al2O3 | MgO | Other |

≥72% | ≤0.5% | ≤1.0% | ≥23% | ≤1.0% | 2% |

3. Physical property of ceramic structured packing:

Index | Value |

Specific gravity (g/cm3) | 2.5 |

Water absorption (wt%) | ≤0.5 |

Acid resistance (wt%) | ≥99.5 |

Loss in burn (wt%) | ≤5.0 |

Max. operating Temp.(Degree C) | 1400 |

Crush strength (Mpa) | ≥130 |

Mohs hardness (Scale) | ≥7 |

4. Technical data of ceramic structured packing:

Type | Specific surface area (m2/m3) | Bulk density (kg/m3) | Void ratio ( %) | Obliquity | Pressure Drop (mmHg/m) | Theoretical Plate(1/m) | Hydraulic Diameter (mm) | Liquid Load (m3/m2.h) | The biggest F factor (m/s(kg/m3)0.5) |

125Y | 125 | 320 | 90 | 45° | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

160Y | 160 | 370 | 85 | 45° | 2 | 2 | 15 | 0.2-100 | 2.8 |

250Y | 250 | 420 | 80 | 45° | 2.0 | 2.5 | 12 | 0.2-100 | 2.6 |

350Y | 350 | 470 | 78 | 45° | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

400Y | 400 | 500 | 75 | 45° | 3.0 | 3.0 | 8 | 0.2-100 | 2.0 |

450Y | 450 | 520 | 72 | 45° | 4.0 | 4 | 7 | 0.2-100 | 1.8 |

500Y | 500 | 620 | 74 | 45° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

700Y | 700 | 650 | 72 | 45° | 6.0 | 7 | 5 | 0.15-100 | 1.3 |

100X | 100 | 280 | 92 | 30° | 1.5 | 1 | 30 | 0.2-100 | 3.5 |

125X | 125 | 300 | 90 | 30° | 1.8 | 1.5 | 28 | 0.2-100 | 3.2 |

160X | 160 | 350 | 85 | 30° | 2.0 | 1.8 | 15 | 0.2-100 | 3.0 |

250X | 250 | 380 | 80 | 30° | 2.5 | 2.3 | 12 | 0.2-100 | 2.8 |

350X | 350 | 450 | 78 | 30° | 3.0 | 2.5 | 10 | 0.2-100 | 2.6 |

400X | 400 | 480 | 75 | 30° | 4.0 | 2.8 | 8 | 0.2-100 | 2.2 |

450X | 450 | 500 | 72 | 30° | 4.5 | 3-4 | 7 | 0.2-100 | 2.0 |

470X | 470 | 440 | 75 | 30° | 5 | 5 | 7 | 0.2-100 | 1.8 |

500X | 500 | 620 | 74 | 30° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

550X | 550 | 620 | 74 | 30° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

700X | 700 | 650 | 72 | 30° | 6.0 | 7 | 5 | 0.15-100 | 1.3 |

Tips: X = 30° (Corrugated Angle of Inclination), Y = 45° (Corrugated Angle of Inclination). The number front of X/Y means the packing’s specific surface area (m2/m3).