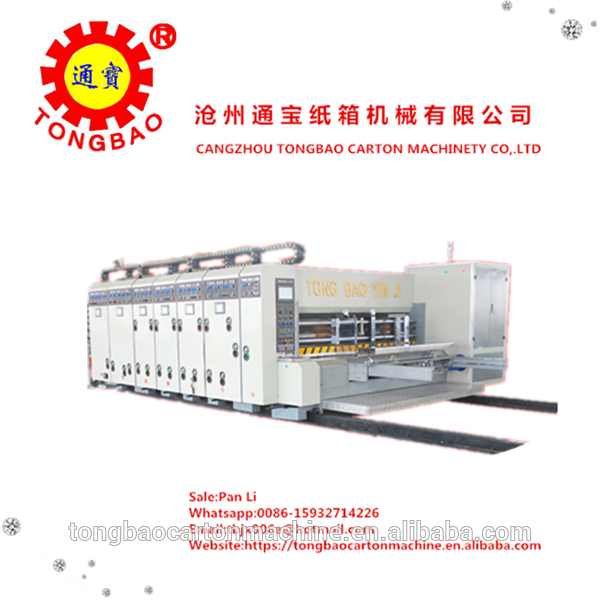

| 原産地: | 中国(本土) | 電圧: | 380v | 銘柄: | tb | 寸法 (L*W*H): | 6.5*2.8*2.04m | モデル番号: | tb | 自動等級: | 自動 | 重量: | 7t | タイプ: | グラビア印刷マシン | 色及びページ: | 多色刷り | 全体のパワー: | 16kw | 使用法: | ラベルプリンター, ペーパープリンター, カードプリンター | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | 保証: | 1年間 | 条件: | 新しい | 速度: | 100個/min |

包装

| 包装: | コンテナ |

SERIAL | WYAZS NAME | UNIT | WYAZS |

1 | Max.Machine Speed | Pieces/min | 120 |

2 | Economic Machine speed | Pieces/min | 100 |

3 | Max.Printing | mm | 1600×2500 |

4 | Max.Cardboard Size | mm | 1600×2600 |

5 | Skip Feed Thickness | mm | 1600×1900×2600 |

6 | Printing Precision | mm | ±0.5(four color ) |

7 | Standard block thickness | mm | 7 |

8 | Slotting Precision | mm | 7 |

9 | Main motor frequency conversion Power | kw | 15 |

Function and Characterristics

1 computer order storing and regulating, faster order changing , convenient operation.

2 Afer the numerical control grinding the wll –plate , important part of the whole machine are made by the high pricision processing center .

3 The quality of all the driving axles and rollers isof good quality steel, high pricision and dynamic equilibrium correction, hard chromium plating, surface grinding .

4 The driving gear is 20Cr Mn Ti alloy steel, carburization and quenching treatment, the hardness is HRC58-62. Long-term use. High precision of color process.

5 The driving part of the whole machine adopts Key-free linking ring to remove the linking space. Suitable for long-term high speed printing .

6 The whole machine adopts spray lubrication.

7 Having the printing , mould cutting and slotting memorizing function. Auto-return –to-zero. Auto-return- to – position.

8 PC ink network control,MCGS software,Seimens low pressure electrical appliance, main engine controlled by frequency conversion, can save electricity for 30%.

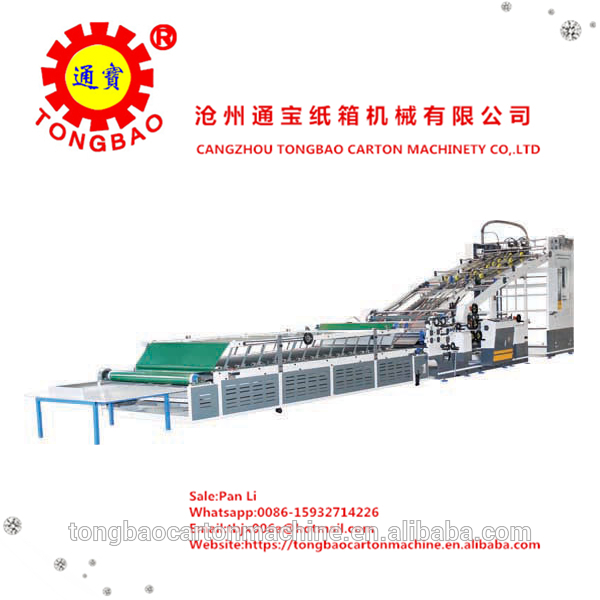

The feeding department

1 Light alloy aluminium back-kicking vacuum absorption paper mechanism Stable operation of the machine.

2 Computer and electronical numerical control of the left and right paperblocking plate and the back blocking box position.

3 Successive or partition paper feeding, infrared ray and photoelectric counting, total-locking mechanism.

Function of printing part :

1 High precision dynamic equilibrium anilox roller. Exquisite printing result.

2 printing phase, computer and electrical numerical control,360 regulation.

3 Crosswise adjusting the printing plate roller, computer and electrical numerical control , t he control range is ±5mm.

4 The space regulation of driving roller , paper rolling roller, rubber roller and anilox roller adopts auto-locking mechanism.

5 plate piping , position returning, printing oil testing , part brake positioning and water ink cleaning mechanism.

6 Installed with fast plate hanging mechanism.

Function of slotting part;

1 The slotting knife pedestal adopts swaying structure. The precise leading screw coordinated with the copper screw nut can move more flexibly and position lore accurately.

2 Computer and elextrical numerical control of the slotting phase and the height of the carton

3 The creasing wheel, slotting knife, ladder paper knife swaying machiney synchronous linking, electric control.

4 The regulation of the space between the slotting and creasing adopts auto-locking structure.

5 Can add protable hole punching mould pedestal.

Function of piling part:

1 The paper-catching arm can be automatically operated or by hand. Installed with safety mechanism to prevent the paeratching arm from sudden dropping and to ensure the safety of the operating personnel.

2 The rising and dropping of the platform is driven by the power chain.

3 The height of pilling is 1600mm

4 With the rising of the cardboard piles the lathe platform ca automatically regulated the tilting height . The elevator attaches the brake function to make the platform to keep the fixed position and not to slide .

5 Pneumatic paper lifting mechanism . When the cardboards have piled to the planned height, the paper-catching holding plate will open automatically, the pedestal will hold the cardboards.

6 The surface corrugation leather belt can prevent the cardboard to slide .