製品情報

| 原産地: 中国(本土) | 銘柄: lingxin | モデル番号: Lxpu- h228、 lxpu- h212、 lxpu- h2107、。。。 |

| 提供される売り上げ後のサービス: 利用できるエンジニア機械類を海外に整備するため | タイプ: のポリウレタン発泡機 | パワー: 39-123kw |

| 自動: はい | プラスチックタイプ: ポリウレタン( pu) | 出力: 60-5000g/s |

| 電圧: 380v | 原料: ポリオールとイソシアン(i soとpol) | アプリケーション: pu製品 |

包装

| 包装: 合板ケース |

仕様

大手技術設計9001と美しい品質サービスisoce認証済み

- Polyurethanes are used in the manufacture of nonflexible, high-resilience foam seating; rigid foam insulation panels; microcellular foam seals and gaskets; durable elastomeric wheels and tires (such as roller coaster and escalator wheels); automotive suspension bushings; electrical potting compounds; high performance adhesives; surface coatings and surface sealants; synthetic fibers (e.g., Spandex); carpet underlay; hard-plastic parts (e.g., for electronic instruments); hoses and skateboard wheels.

- Our Equipment features:

1. High Pressure Infusion Mixing Head:

- The L type twice mixing infusion head adopt high quality alloy and the most advanced heat treatment process in China.The hardness could be reach to above HV900,the module processing by precise device and make sure the components accurate and clean appearance,no failure for using more than one hundred million times.Two kinds of materials hedge mixed in hybrid champer through high prssure atomizing to form vortex to mix them for twice,kaming the mix fast and effectual,the speed of material shafts and clean shafts are so fast and can be infused repeatly.All cleaning can be finished by clean shafts without wastin materials.

2. High and Low Pressure Switching Valve:

- The adoption of high pressure resistant 35Mpa stailess materials optimizes the valve structue and ensure the pressure resistance and anti-abrasive seal without leaking for long term usage.The limit switch in the valve makes operations right and observable.The pressure transformed fast without pause,which will lift the infusion speed.Transforming between high and low pressure freely will lower the pressure and energy consumption of the system and reduce the wear and tear of equipment at non-infusion time,meantime,extend their service life.

3. Permannent Magnet Joint Shats:

- It is a new kind of joint shaft,which connects power unit and driver unit by means of premanent magnet.It doesn't need to be connected with machineries,with the interaction between rare earth and permanent magnet plus magnetic can penetrate certain space and physical materials,the mechanical energy can be dilivered.The permanent magnet joint shaft consists of outer rotor,inner rotor and isolation set,which solves the leaking issues in seal and troubles of changing the material pump seal frequently thoroughly.

- Human-computer interface:

- The use of big touch screen makes the operation intuitive,be easily understood and avoid error efficiently.With

- large amounts of automatic control technology will ensure equipments work safely.For there is a build-in fault diagnosis system,all equipment data will be found observable,if there have any fault,corresponding tone and light will point out and the system will stop working automtically to protect equipments and operators

4. High Pressure Plunger Pump:

- Supplied in set by two famous PU special pumps manufacturers,one is Germany Rexroth,the other is China Gelanrc,Lingxin has established long term cooperation with them.

- Characteristics as following:

- The measurement of all kinds of flow rate are highly accurate.

- --equipped with accurate measuring scale hand wheel to control the flow rate manually,ensure adjustment accurate and work steady.

- --working pressure can reach up to 25Mpa.

- --inlet wth low pressure can deliver high viscosity by pumps.

- --For using special matched materials and sealing,the parts of pumps and the delivered materials(such as isocyanate) are compatible.

- --low flow pulsation and high volume efficiency.

Technical Parameter:

-

Injection Output:

60-5000g/s

Repeat injection accuracy:

±1%

Material tank volume:

250L-500L

Compressed air needed:

Dry,oil free P:0.7Mpa Q:600NL/min

Injection pressure:

10-20Mpa(adjustable)

Temperature control system:

Heat: 2×9Kw

Mixing ratio range:

1:5~5:1(adjustable)

Input power:

Three-phase five-wire 380V

Injection time:

0.5~99.99S(correct to 0.01S)

Total power:

39KW-123KW

Material temperature controlling error:

±2°C

Raw material viscosity(22°C):

POLY ~2500MPas

ISO ~1000MPas

Foam Application:

polyurethane rigid foam

polyurethane flexible foam

polyurethane integral skin

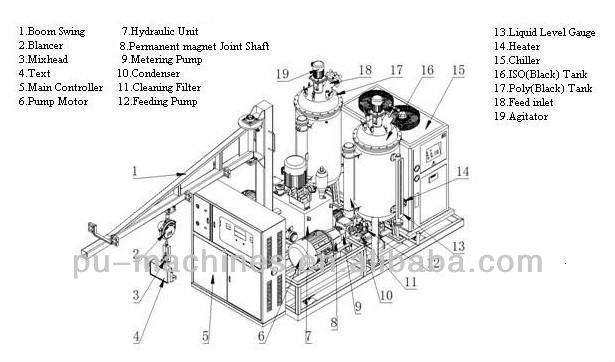

Main Componnet Diagram:

Final Product examples:

- Car cushions, head cushions, steering wheels, bumpers, instrument boards, sunshade boards, motor bicycle cushions, thermal insulation materials, refrigerator materials, roof insulating slabs, office chairs, handrails, fitness equipments, medical appliances, building materials, etc.