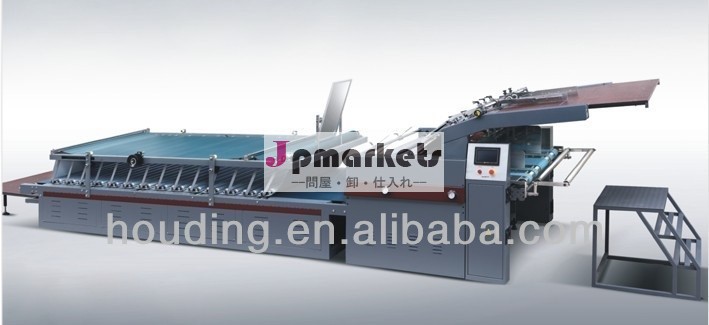

製品情報

| 条件: 新しい | タイプ: ペーパー打抜き機 | コンピュータ化される: はい |

| 原産地: 中国(本土) | 銘柄: houding | モデル番号: Hd-1400d |

| 電圧: 380v | 力(W): 15キロワット | 次元(L*W*H): ミリメートル9500*3300*1800 |

| 重量: 12000kg | 認証: ce | 保証: 12ヶ月 |

| 提供される売り上げ後のサービス: 利用できるエンジニア機械類を海外に整備するため | 名: 高速automatc用紙ロールシーター | 最大。 を切削幅: 1400ミリメートル |

| 切断の長さ: 450〜1400ミリメートル | 固定長の精度: ±0.2mm | 速度: 350倍/min |

| 総電力: 15キロワット |

包装

| 包装: 木製ケース |

仕様

高速自動紙シーター1,セリウムの証明書2,操作しやすい3,高品質とリーズナブルな価格4,良いサービス

Automatc Paper roll sheeter

Performance and Characteristics:

(1) This paper cutting machines is suitable for cutting big rolling packaging materials such as paper, paper board, Kraft paper. Culture paper, Printing paper, laser ra paper, aluminum foil paper laminated paper, etc. Widely used in paper industry and printing industry.

(2) Adopts EU and JAPAN electronic parts, more neatly control with computer and mechanical technical

(3) Automatic photocell tracing.

(4) AC servo motor drive, high speed cutting steadily

(5) Adopts imported precision cutting blade, it is in high precision

(6) PLC control with touch screen, easy operation

(7) Compare with other models, this machine equipped with automatic side guiding system, and tension control system, paper delivery well, and cutting exactly

(8) It adopts shaft-less shaft loading paper rolls

(9) It has the functions of easy operation, high precision, good stability, low noise.

Main Technical Parameters :

Machine Model | HD-1400 Model |

Maximum width of roll | 1450 mm |

Machine power | 15kw |

Machine weight | about 12000kg |

Overall size | 9500×3300×1800 mm |

Power supply | 380v/220v/50Hz (three phases) can be made according to customer’s customer |

Air pressure | Max 5.5kg/cm2×5m3/min |

Max diameter of roll material | ≤1800 mm |

Material thickness scope | 850gsm(according to different material) |

Cutting Length | 450——1400mm |

Cutting Precision | ±0.2mm |

Unwind roll inner core | 3"or 6"(or according to customer) |

Cutting speed | 350times /min |

Cutting style | Lower cutter fixing, upper cutter is rotary |

Unwinding rolls | 1 rolls |

Height of stacking | ≤1300mm |

Main specification:

1.High precision rotary cutter and cuter seat(Germany high speed bearing) 1unit

2.Paper edges and corners adjusting system (Taiwan) 1unit

3.Static avoid device (Taiwan) 1unit

4.High speed steel cutter (Taiwan and Germany) 1unit

5.Cutting side round cutters and cutting set (upper and lower 3 units

6.Automatic meter counting label insert device 1unit

7.Paper transportation device 1unit

8.Automatic paper stacking system 1unit

9.Man-machine interface touch screen (Taiwan Hitech) 1unit

10.Servo system and motor 15 kw (imported) 1unit

11.Frequency controller 7.5kw &1.5kw (imported) 1unit

And frequency motor 5.5 kw & 1.5kw (imported)

12A. 2 roll oil press shaft-less shaft 1unit

12.B. High lever England brake and dish, control the air valve by computer program

13. Upper ,lower dust inhaling system parts 1unit

14. Appendix parts 1unit

15.Retroflexion shaft 1unit

16.Auto error-collection adopts Taiwan pneumatic system 1unit

17.Machine body is painted with imported paint 1unit

18.attahced with hallway structure 1unit

19.Tension adopts shanghai automatic control system 1unit

Details:

A-1:Hobbling Rotary cutting.

1)Upper blade: Adopts SHM (England) cutter style to avoid the noise when cutting, extend the using life. Upper blade roll adopts copper sealing processing,

2)Lower blade: cutter set adopts cast iron, high precision processing, steady running

3)Initiative roll: has outspread veins , use air chamber to control the roll to load clamp the paper

4)Safe cover : when open the cover, the machine will be stop to be safe

A-2:Paper edges and corners adjusting system

1):Type :Adopts England SHM Cutting sets

2):Control style :adjust according the scale on operation panel.

A-3:Static avoid device

1)Model: Static avoid stick and ion deviser to remove the static on paper

2)Main machine:High efficient ion deviser

3)Static avoid scope : 1400mm width

A-4:Taiwan Germany high speed copper:1450mm length,HSS 18%W

A-5:Round cutter and cut blade :three sets upper round and lower cutter

A-6:Automatic counting label insert device

1)Style:inset after extract counting

2)Function:A)Input the inserting numbers on the PLC

A-7:Paper sheet delivery device

1)Type: delivery with multi-moments (with dust inhaling fan)

2)First step delivery: at one time with the speed of loading paper

3)Second step delivery:can be single jog,or continue jog, the speed is slower than firt step to let the paper coming out in order

4)Paper collecting :automatic stacker for the counting papers

A-8:Automatic paper collecting and stacking

1)Model:hydraulic pressure lift up and down paper stacker ,it will be automatic down when the paper stacked in quite a height

2)Maximum stacking height 1300mm(15”)

3)paper collecting size:W=1400mm(55”),L=1450mm(57”)(or specially make according to customer request)

4)Wight support:2000kgs

5)Stacker: A:Electronic stacker 1.45m

B:pneumatic two side paper stacker

C:Back fender can be adjustable

A-9:Electronic control system(Schneider Electric)

1)Touch Panel screen (Taiwan Hitech)

2)CPU (Germany Siemens)

3)Coder (Japan Nemicon)

4)PLC (Germany Siemens)

A-10:Drive motor

1)Paper delivery AC Motor 1unit

2)The second step delivery belt frequency motor 1unit

3) Paper collect lifting hydraulic system 1unit

4)Face collecting paper AC Motor 1unit

5)Mother roll loading AC Motor 1unit

6)Frequency controller(7.5kw&1.5kw) (7.5kw&1.5kw) 1Kit total power 30kw/unit

A-11:Hydraulic shaft less paper shaft

1)Maximum paper roll diameter:1800mm(71”)

2)Maximum paper roll width:1400mm(55”)

3)Minimum paper roll width:500mm(20”)

4)Paper roll inner diameter:3”-12”

5)oil press drive unit:2.2kw

6)paper clamp arm moving, oil press drive

7)paper clamp arm lifting ,oil press drive

8)Air pressure brake(import)

9)Control valve(Japan SMC)

10)Paper guiding roll and shaft

A-13:Upper and lower dust inhaling system

A-14:Accessories

1)Germany high speed steel upper and lower cutter one unit(Taiwan)

2)Label paper 5 rolls

3)tools one unit

4)transformer (380V/220V) one unit

A-15:Retro flexion shaft one unit