| 原産地: | 中国(本土) | 電圧: | 110ボルト〜480ボルト | 銘柄: | jke | モデル番号: | zfs | 力(W): | 1.5kw | タイプ: | 真空吸気 | 材料: | ステンレス | 構造: | コンベヤ・システム | 認証: | ce | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | 積載容量: | 100〜6000キログラム/時間 | 条件: | 新しい | 物質的な特徴: | 耐熱 | 次元(L*W*H): | 600ミリメートル* 1000ミリメートル* 1200ミリメートル | 作業状態: | 真空 | 制御システム: | plc | dicharge: | 自動搬出装置 | レベルチェック: | 材料レベル制御システム |

包装

| 包装: | 燻蒸の送料合板ケース+木製パレットまたはに応じて顧客の要求。 |

ZFS Negative Pressure Powder Conveyor System

Product DescriptionZFS Negative pressure powder delivery system is an integrated system conveying powder through vacuum suction and combined with filtering, reverse flow, feeding, valve controlling. System is mainly used in conveying powder, granular and powder mixtures, etc.; System can automatically transfer various materials to the feeder of packaging machines, injection moulding machines and pulverizer, but also can transport mixtures to the mixer and all kinds of mixed reaction tank directly. It solved the dust problem when feeding and reduced the labour intensity, as the preferred powder delivery system.

Working ProcessWhen the fan pumped air from powder collecting tank, strong negative pressure would be generated in the tank, and powder would be sucked with the air into powder collecting tank through the suction pipe. Filters in the powder tank will effectively prevent dust and small particles pumped out with air. In this process, accumulator tank next to the powder collecting tank is filled with the air of certain pressure. When the suction is finished, air in the accumulator tank will be released instantly, which will back blow the filter and overblow adsorption in the filter. So the core of filtration can maintain a normal filtration area and won’t affect the yield.

When the system starts running, the unloader beneath powder collecting tank begins to work with continuous blanking. In order to prevent accumulation of powder, the high-frequency oscillator is installed beneath the tank to ensure a smooth blanking of powder.

Intermittent blanking will be selected at small powder feeding. Gas jet will lead to negative pressure. When powder tank is filled with materials, suction will automatically stop controlled by material position monitor, then purge-air port and pneumatic discharge valve open. When the material level below the material position monitor, discharge valve shut down to pump material again. Continuous or intermittent above blanking process can be set by the PLC and automatic controlled.

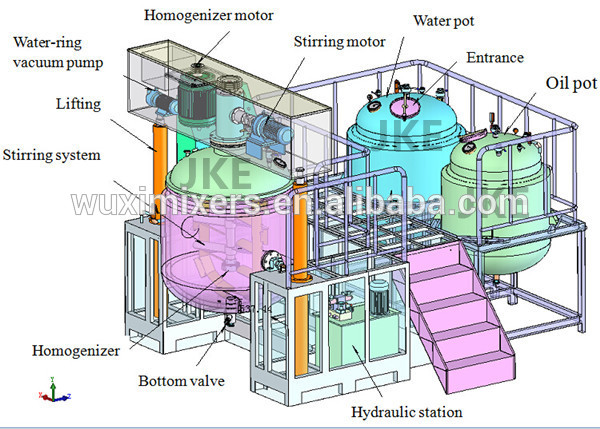

ComponentsThe entire vacuum powder delivery system is composed of the following components:

1.Powder collecting tank

2.Filtration system

3.High-pressure fan unit and valve

4.Accumulator blowback and pulse system

5 Automatic unloading device

6.High-frequency vibration assisted discharging device

7.Material level control system

8.PLC automatic control system

9.Absorption and discharge piping valve system

Technical Parameters

Type | ZFS-1 | ZFS-2 | ZFS-3 | ZFS-4 | ZFS-5 |

Fan Power( Kw ) | 1.5 | 2.2 | 3 | 4 | 5.5 |

Unloader Power( Kw ) | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 |

Transmission Capacity( Kg/h ) | 100~750 | 750~1500 | 1500~2000 | 2000~4000 | 4000~6000 |

Note: Transmission capacity is determined by the proportion of powder, particle size, gas content, mobility and other physical factors.