| 原産地: | 中国(本土) | 銘柄: | hexie | モデル番号: | Hx-130 | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | 金型長さ: | 4-16meter | 分間トップ直径: | 130ミリメートル | 直径最大上部: | 550ミリメートル | アプリケーション: | コンクリートポールの生産 | 意図されたポール: | 角ポール、 ひずみ力ポール、 直線ポール | 適用規格: | ユーロコード、 私達コード、 中国のコード | 毎日最大容量: | ポールの50個を | qcシステム: | 国際的な第三者検査 | 参照されたテーパー: | 0.013/0.015/0.018 | インストールとテストのための命令: | マニュアルや図面のためのインストールとテスト |

包装

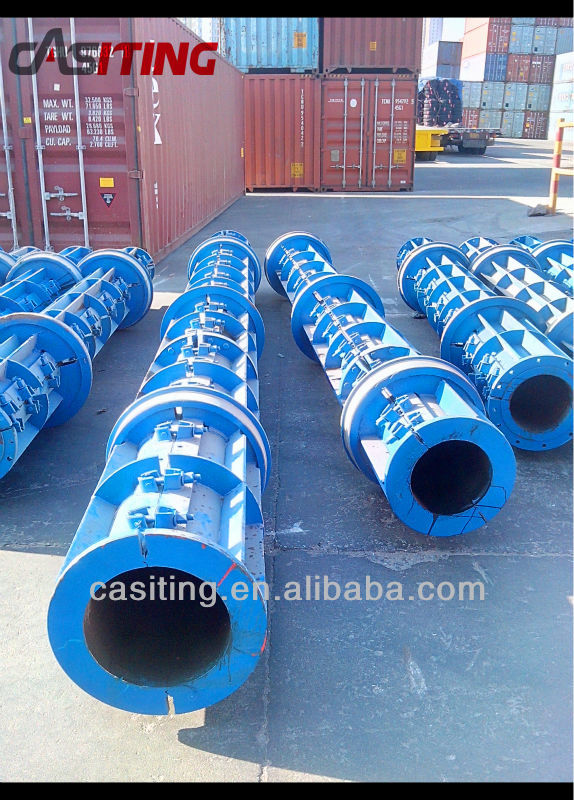

| 包装: | 通常のコンテナでヌードパッケージまたはトップオープンコンテナ金型用、 長さに起因する、 に独立したセクションまたは全体で配達。 クレーン用、 に独立したセクションと作業現場にインストールする。 |

A.Brief of Electrical Concrete Pole

I.Electrical Concrete Pole Look:

Electrical concrete pole can be made in many shapes.Poles up to 40 feet long with square or rectangular solid cross-sections are easy to manufacture,occupy less room during transporation,and faciliate positioning of steel at corners for maximum resisting moment at a given depth.Circular hollow cross-sections are better for longer poles.Because hollow,weigh less.And because they are spun at high speeds in casting operation,then concrete is denser and stronger.

II.Design Consideration:

A pole generally acts as a cantilevered structure ,and should be designed and analyzed as a tapered member with combined axial and bending loads.Because shear forces are small compared to bending moments,electrical concrete poles are very resillient.Axial loads are small,too,and are generally ignored except when the structure is guyed.

III.Working Principle:

Electrical concrete poles generally are manufactured in Centrifugal casting process.Centrifugal casting or spin casting is the best and cost-saving method for electrical concrete pole production.In centrifugal casting,a steel form(mold) is placed on machine,partially filled with amount of precalculated concrete ,then spun for several minutes(time for spinning depends on motor speed).The tremendous centrifugal forces created by the spinning consolidated the concrete by forcing it against on the wall of the form.Excess water that is squeezed out of concrete is poured from the hollow cavity created in the center of the pole.After spinning,the form is steam cured until the strength of concrete is 3500psi.The prestressing wire is then released,and the pole is air-cured for 28 days.The result :a hollow pole made of dense concrete.

B.Process of Production

E.After Sales Services

Our ServicesAfter Sales Services:

Commissioning Engineer:we will send commissioning engineer as your request to help you install and test our machines till they are running well.

F.FAQ

1.How to selec process for electrical concrete pole production?

Answer:the production process of electrical concrete pole depends on its application.The mechanical property of electrical concrete pole depends on concrete and steel.Using different steel,the production process have little differences.

2.How to selec equipments different process?

Answer:The production process of electrical concrete pole generally have steps below:

1.Steel structure production→2.Concrete pouring→3.Tensioing→4.Spinning→5.Steam curing.

All the selection of equipments should be based on the process above.

3.Why we selec your equipments?

Answer:our durability,adaptability for different production process and working environment,and price performace will meet your demands.

4.How to check the quality of equipments?

Answer:we have a series of regulation on factory inspecation to guarantee each machine is healthy for working.