| 原産地: | 中国(本土) | 電圧: | 380ボルト220ボルト | 適用: | 生産石膏粉末 | 製品容量: | 100% | 銘柄: | 呉興 | モデル番号: | wx-45 | 自動等級: | 自動 | 重量: | 140 t | 力(W): | 110kw | フューチャー: | 安定した | 認証: | ce、iso | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | 保証: | 1年 | 条件: | 新しい | 次元(L*W*H): | 100 × 30 | ワン: | ホイスト | 二つ: | 穀物倉庫 | 三: | electromagetic振動フィーダー | 四: | レイモンドフライス盤 | 5: | 分布 | シックス: | 垂直フライパン | セブン: | バーナー | eighter: | 誘引ファン | ナイン: | 耐火レンガ | 名前: | 石膏粉末植物 |

包装

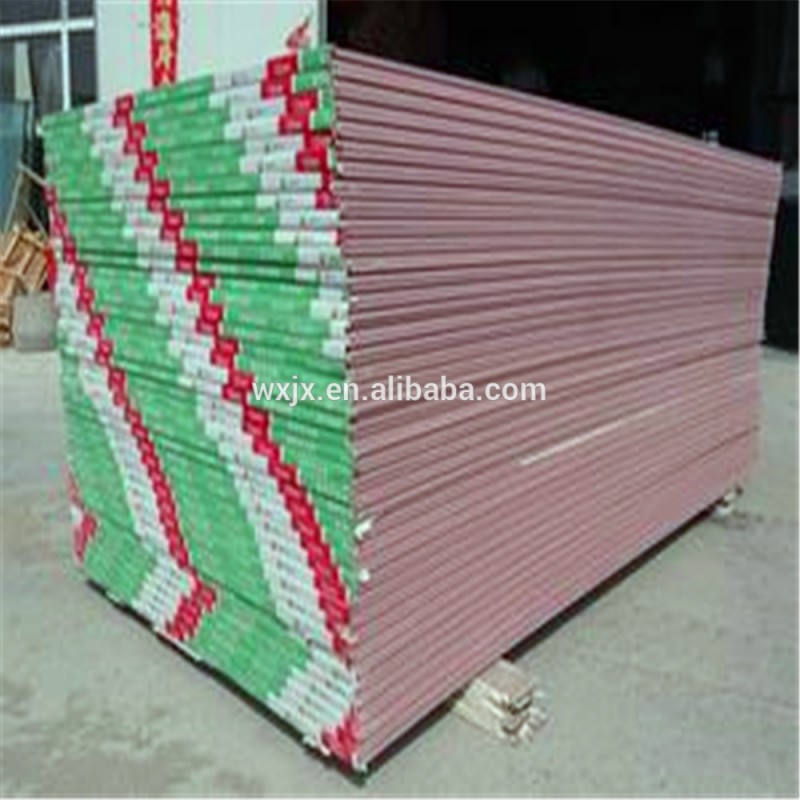

| 包装: | コンテナ |

gypsum powder plant

Introduction of the gypsum powder plant

Gypsum powder plant | 30,000 ton/year~240,000 ton/year |

Automation | fully automatic |

Calcination system | 1.using boiling furnace to calcine 2.adopting heat conductive oil furnace as heat source |

Fuel | coal, natural gas, heavy oil, diesel oil |

Main materials | natural gypsum rock, desulfurization gypsum, dephosphorizaiton gypsum |

Standard of product quality | In conformity with national standard “GB/T 9776-2008 construction gypsum“ |

Crushed process flow introduction

Crusher breaks up large sized gypsum ore to small granule less 25mm. and then, separator mil the granule to powder with required fitness and deliver to boiling furnace to calcine. the calcined gypsum powder is delivered to grog bin for saving or production workshop for producing.

Working theory

the main part of boiling furnace is composed of thin and dense radiator pipes, which is filled with conduction oil to release the heat to the inside of the furnace.Equipped at the bottom of the furnace, the roots blower makes the powder inside the furnace into the boiled state. The powder material, backed and dehydratend with crystallization water at certain temperature flow out through the outlet automatically. the gypsum powder produced by this procedure has stable quality and well controlled crystallization water rate, inital and final set time. further more, by using dry electrostatic cleaner, the equipment has over 95% dust collection efficiency and eliminate the dust polltion.

.jpg)