| 電圧: | 380 | 原産地: | トルコ | 銘柄: | starmax | 条件: | 新しい | モデル番号: | ヨーロッパ製品ペレットミル部品/ペレット工場ペレット/ペレット | 重量: | 10000キログラム | 力(W): | 250 kva | タイプ: | 供給の餌機械 | 保証: | 2年 | 認証: | ce | 次元(L*W*H): | 12 × 20 × 12 mt | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | ペレットシステム原産地: | ヨーロッパ、トルコ | ダイ: | X46cr13原料 | ダイとローラー: | 製オランダandritz | コンディショナー&フィーダー: | クロムニッケル | 容量: | 1.500キログラム/時間または3.000キログラム/時間 |

包装

| 包装: | 包装は変えるによれば購入システム機器。用ば完全に、それが必要2ユニット40フィートハイキューブコンテナ。 |

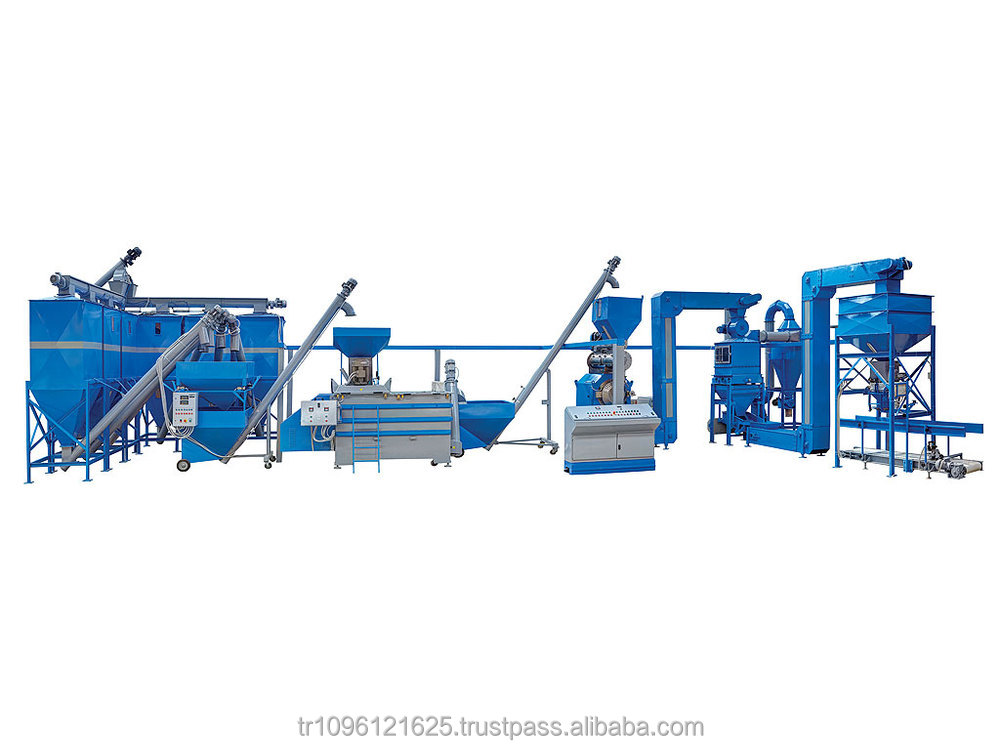

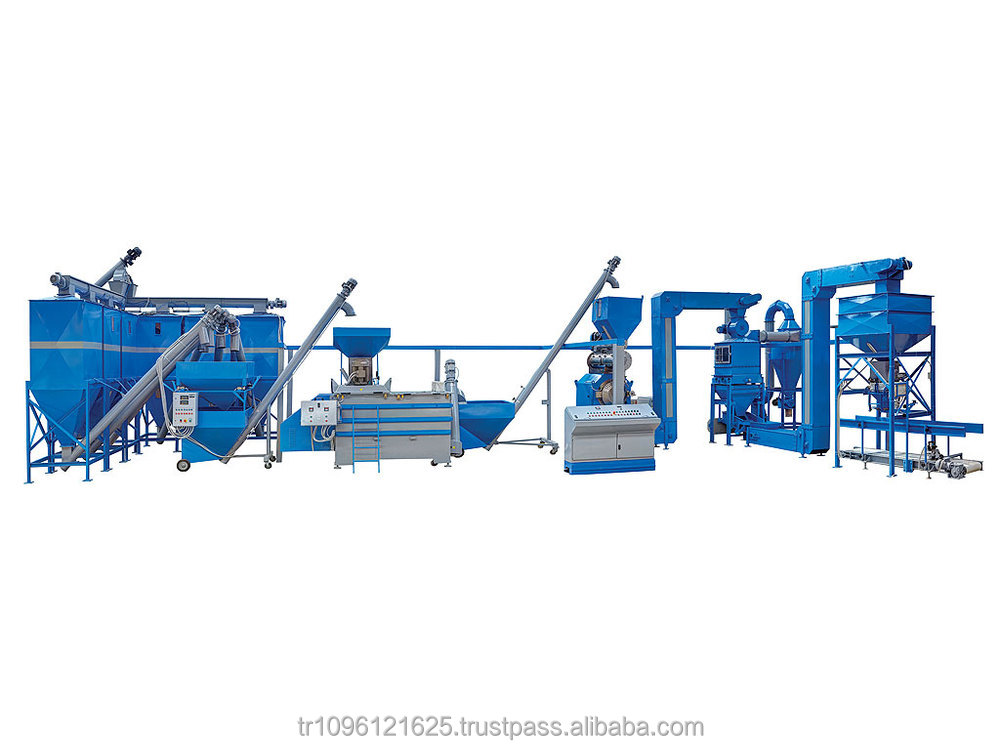

European Product Pellet Mill Parts / Pellet Mills Pellet / Pellet Packing Machine

Capacity:

· Prostar 1500 1.5 T/H

· Prostar 3000 3.0 T/H

Area Of Use

· Cattles, Sheep and Goats, Fattening and Dairy Feeds

· Poultry Feeds

· Organic Fertilizer Pelletizing

· Prina (olive oil waste) Pelletizing

Who Can Use

· Large-Scale Farms that Want to Produce Their Own Feeds

· Medium-Sized Feed Producers

Advantages

· Turnkey feed factory from raw material purchase pit to packaging

· Professional system, economical price

· Low energy requirement

· Project designing depending on your need

Working Princibles

RAW MATERIAL TAKING: Cereals are discharged into the, raw material taking pit. The pit has an upper grill with a capacity of 20-25 tons.

SILOS: Products are carried to the upper helixes of silos by means of a bucket chain and the intended silos are filled up through pneumatic covers.

RATIONING: Raw materials coming from silos are gathered in the bunker of rationing unit depending on the content prepared. After the weighing process, they are switched to the lower bunker.

GRINDING & MIXING: Cereals are carried by horizontal helix and bucket chain to the GRINDING unit. The products passing through the horizontal type-GRINDING unit go down to the mixing unit.

The products to enter into the mixer without GRINDING are weighed at simple scales and carried to the mixing unit by a helix. The additives such as minerals, vitamins, bone dusts, etc. suitable for the quality of ratio are added through a cover on the mixer. Homogeneous mixture is reached with the double-helical system. After a mixing process of about 5 minutes, the pneumatic cover is opened and the product goes down to the lower bunker of mixer.

The powder feed bucket chain has two-output valves. Optionally, powder feed can be directly sent to the packaging. If pelletized feed is to be made, the product is sent to the pelletized feed upper bunker.

PELLETIZING: Powder feed comes from upper bunker to feeding helix. The feed helix is made of 304-quality stainless steel and has a speed control.

The main duty of the conditioner is to enable the dry steam given to the powder feed to be distributed homogenously. It is made of 304 quality stainless steel.

Dry steam required is given to the conditioner by a boiler.

Disc X46Cr13 is made of special raw materials. Discs and rolls are manufactured and specially designed by Andritz, a company based in Holland.

COOLING: The product taking out of the pelletizing machine hot by Z conveyor is taken to the cooling cabin. Cooling is performed by an inverse current system controlled by a three-grilled, brake-reducer. Powder and hot air are removed from the cabin by means of a cyclone and fan. The cooled product falls down by means of heat sensors in the cooling cabin and goes to the rotary screen for screening. The dusts remaining on the pellet are removed by a rotary screen system.