| 原産地: | 中国(本土) | 電圧: | 220v/380v/415v | 適用: | プロフィール | 銘柄: | qichang | モデル番号: | Sj-51/65/80/92 | 自動等級: | atomatic | 重量: | 4t | 力(W): | に応じてにマシンモデル | 認証: | ce | 処理されるプラスチック: | PVC | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | ねじ設計: | 二重ねじ | 条件: | 新しい | 次元(L*W*H): | に応じてにマシンモデル | スクリュー: | ダブルスクリュー | 材料: | 塩ビ廃プラスチックや廃天然木製の粉 | 処理の程度: | カットすることができ、 塗料、 結合しており、 釘やボルトで固定 | wpc製品形状: | 異なる仕様のみを変更し金型 | モーター: | ドイツのジーメンスモーター | コンバータ: | 台湾デルタコンバータ | コンタクタ: | フランスシュナイダーコンタクタ | コントローラ: | 日本rkc/オムロンの温度調節器、 |

包装

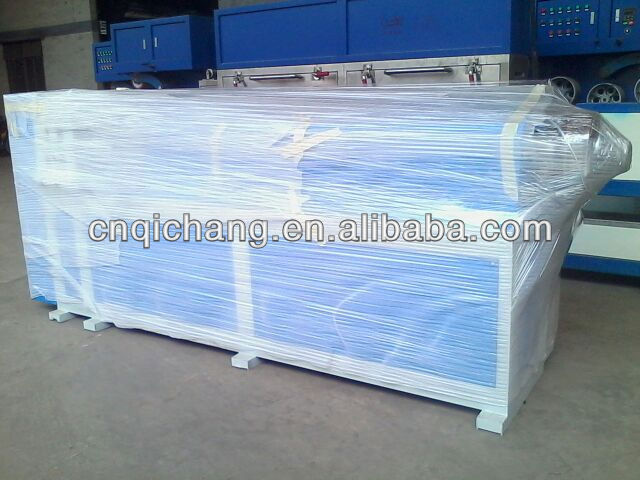

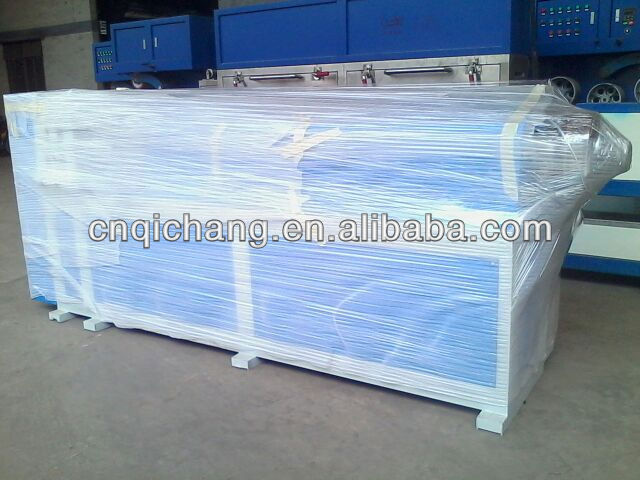

| 包装: | 通常の |

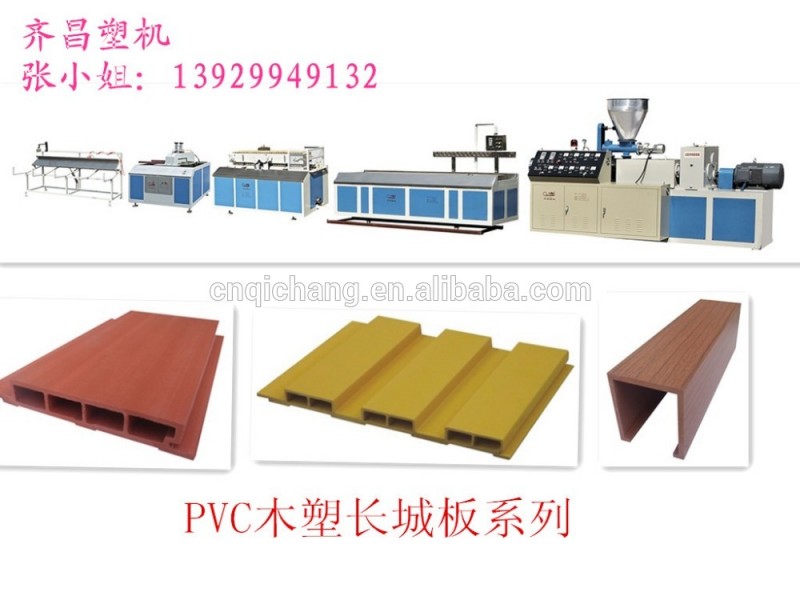

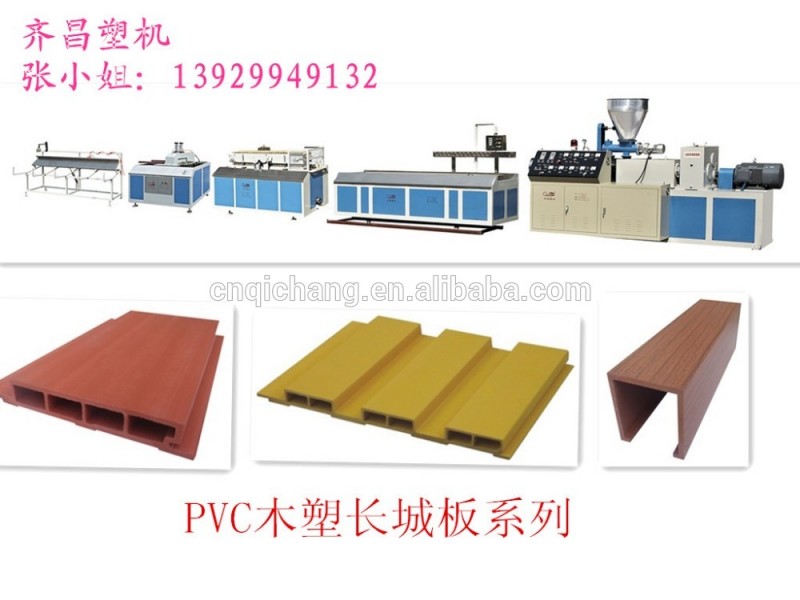

The whole production line includes the following parts:

1.SRL-Z300/600 or SRL-Z200/500 mixing machine

2.Automatic feeding machine

3.SJSZ-65/132 twin screw extruder

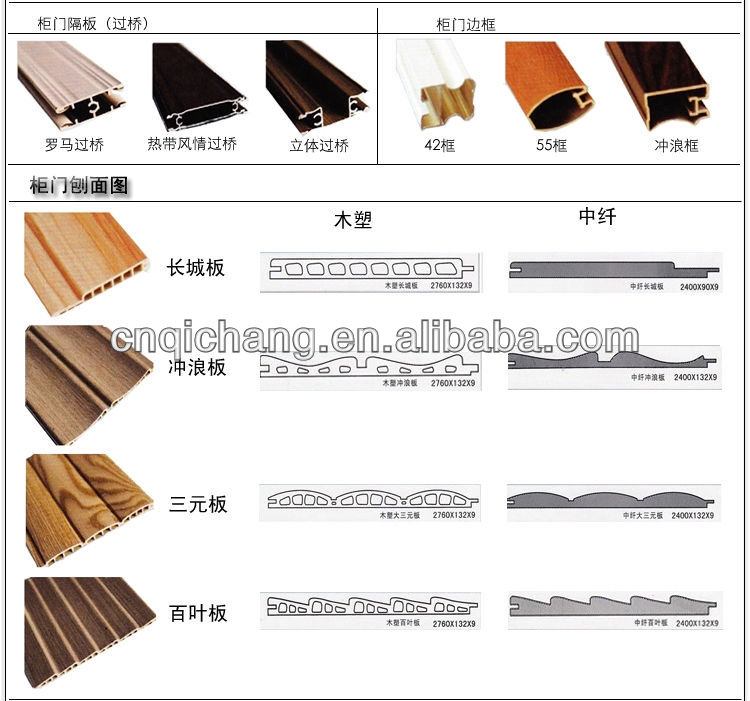

4.profile molds (make according to your requirements)

5.Vacuum cooling shaping table

6.Hauling off machine

8.Cutting machine

9.Automatic Stacker

10.Recycling machine

Advantage and application:

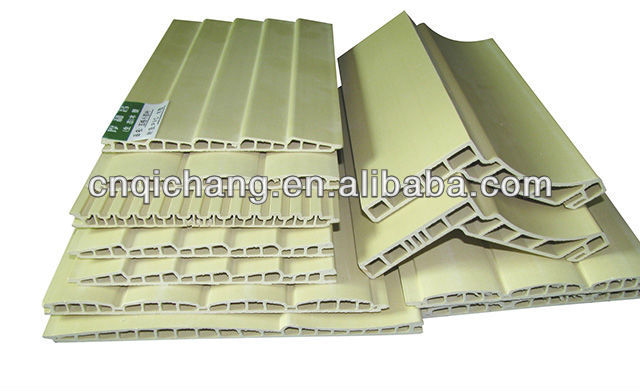

1.the excellent appearance of the natural wood,

2.With the advantages of anti-corrosion, moisture-proof, anti-moth-eaten, no cracking, etc, it is much harder than the pure plastic products and has the similar process-ability as the wood.

3.It can be cut, paint, bonded and fixed with nails or bolts.

4.The woodplastic foamed board is mainly used in wall panel, decorating plate, construction formwork, kitchen cabinet, cloth cabinet, bath room cabinet, fence, stair handrail, etc.

Complete process:

Raw material +wood power+ additive → mixing → granulating → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum cooling calibration table → belt haul-off → cutter → rack → finished product →Recycling of unqualified products were broken

The main technical parameters | |||

Item | SJSZ-45 | SJSZ-51 | SJZ-65 |

Screw diameter(mm) | 45/100 | 51/105 | 65/132 |

Screw volume (mm) | 2 | 2 | 2 |

To screw | The outward differences Screw rotation direction | ||

Screw Rotational Speed(r/min) | 1-37 | 1-32 | 1-34.7 |

Screw effective working length (mm) | 985 | 1070 | 1440 |

The main motor power (kw) | 15 | 18.5 | 37 |

Barrel heating power (kw) | 12 | 18 | 24 |

Installation Power(kw) | 27 | 32 | 65 |

Production capacity (kg/h) | 95 | 80-120 | 250-300 |

High machines Center(mm) | 1000 | 1000 | 1000 |

Weighing (kg) | 2800 | 3200 | 4000 |

External dimensions | 3620×1050×2157 | 3000×1050×2200 | 4235×1520×2450 |

Established in 1997,QiChang Plastic Machinery Factory has achivments in the plastic machine field.

Company introduction:

1,Specializing in plastic extrusion machinery and plastic auxiliary production.having been found for more than twenty years since 1997

2,With excellent processing equipment and a team of dedicated professionals

3,Provides recipes from raw materials, production operated processing operating staff training and so a full range of services

4,Products being sold to all over the world including the Middle East, the Americas, Russia, Europe, South Asia and etc.

Operating system: