| 原産地: | 中国(本土) | 銘柄: | 完全 | モデル番号: | WL15078 | キーワード: | 板金 | 利用可能な材料: | 鋼、 ステンレス鋼、真鍮、 アルミ | 原産地: | 山東、 中国(本土) | 支払い: | t/t、 l/c、 d/p、 とその他 | ブランド名: | 完全 | 証明書: | iso9001: 2008 | 品質管理システム: | 100%検査前に出荷 | 設計: | に応じて顧客の図面やサンプル | 精密: | ± 01ミリメートル | 厚さ範囲: | 0.5〜7ミリメートル |

包装

| 包装: | 輸出標準カートン または木製ケース または に従って顧客の特別な ニーズ板金 |

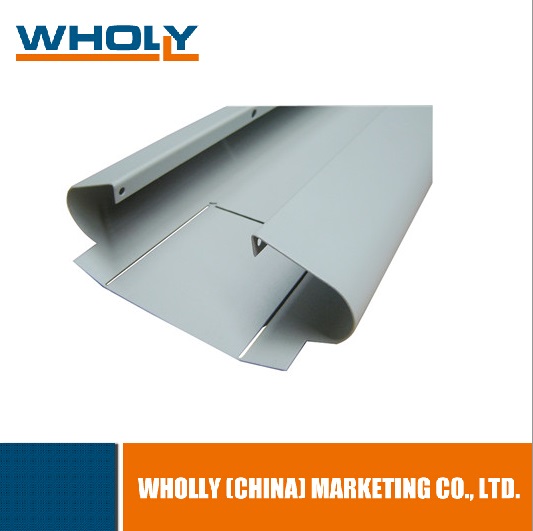

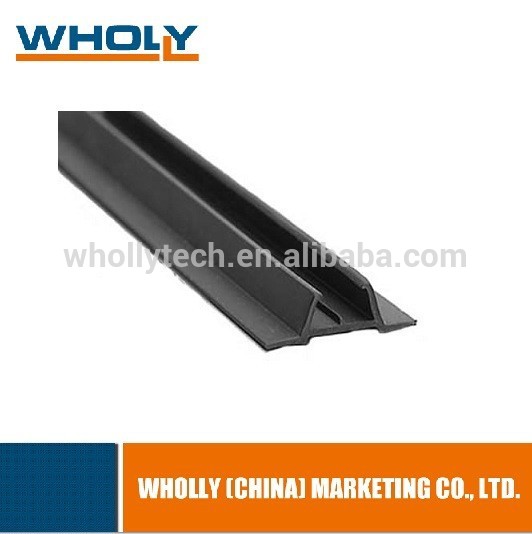

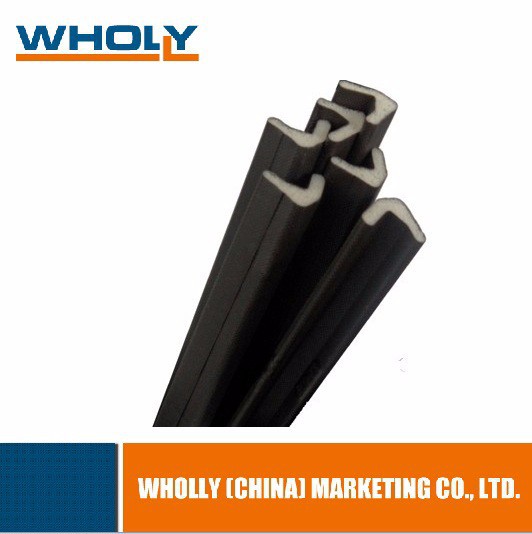

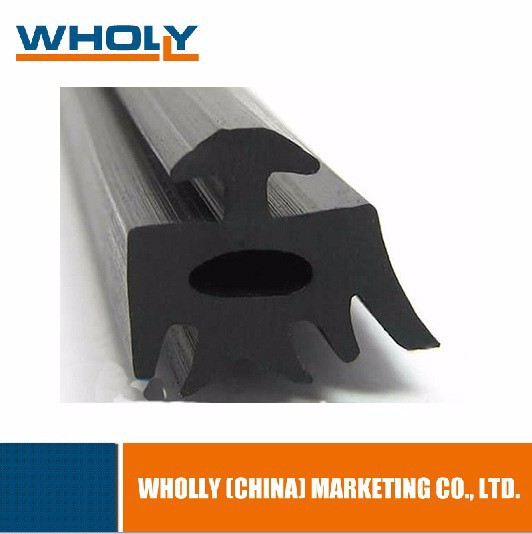

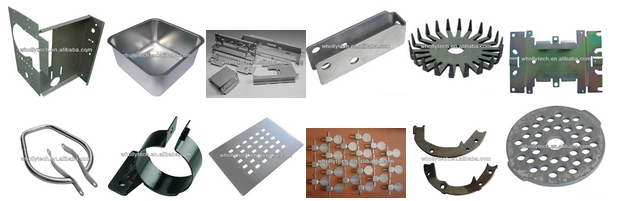

Factory supply best quality sheet metal stamping

Product DescriptionSpecifications

1.Reliable work,widely used

2.Fast delivery

3.Small investment,quick effect

4.Easy operation

Equipment | 1) Stamping Machine, Oil Hydraulic Pressing Machines, Riveting Machine, Welding Machine |

2) CNC Milling and Turning, Grinding, Honing, Lapping, Broaching and other secondary Machining,Meter Lathes | |

3) Line-cutting Machine, Laser-cutting Machine | |

Test Equipment | Hardness tester,Chemical analysis,Digital Measuring Projector, Dynamic Balancing Tester, Plating Tester |

Material Available | Copper, Brass, Carbon Steel, Stainless Steel, Aluminum, Zinc, Bronze, Steel, etc. |

Surface Treatment | Silver/Zinc/Nickel/Tin/Chrome/Plating,Pickling, Powder Coating,Hot Galvanized,Polishing, Brushing, etc. |

Production Process | Laser/Line cutting, Stamping, CNC Punching,CNC Bending,Welding,Assembling,ect. |

Standard | IEC. ANSI. API. BS. DIN. JIS. GB. etc. |

Certificate | ISO9001-2000 |

R&D Capacity | Professional Tooling development &process &design |

Inspection | IQC,IPQC,FQC,QA |

Features | Customized Design, Small Order Allowed, Sample Product Available, Competitive Price |

Payment | TT, L/C, Western unio, etc. |

Delivery time | 7-30 days after get the deposit |

Service | We have annual capacity of 10,000tons. based on our honesty, passion and capacity, we devote e to supply the best service to customers, who will be warmly welcome to visit us |

Packing | Carton, Wooden Case, Pallet etc. |

Manufacture Capability

| Typical | Feasible | |

| Shapes: | Flat Thin-walled: Cylindrical | Thin-walled: Complex |

| Part Size: | Area: Up to 10 mm² Weight: 0.5g-200KG | |

| Material: | metals Carbon Steel Stainless Steel Aluminum Copper | Lead Magnesium Nickel Tin Titanium Zinc |

| Surface finish -Ra: | 3.2 - 12.5 μmm | 1.6 - 25 μmm |

| Tolerance: | ± 0.1 mm | ± 0.1 mm |

| Max wall thickness: | 2 - 15 mm | 1 - 25 mm |

| Advantages: | Can form complex shapes Many material options High production rete Low labor cost Short lead time possible | |

| Disadvantages: | Limited to constant part thickness Part may require several operations and machines Large amount of scrap | |

| Applications: | Brackets, panels, cans, utensils |

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper, Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

Products All stamping and punching is available

If you have any question, feel free to contact us:

Company name | Wholly(China) Marketing Co.,Ltd |

Contact person | Mary.Wang |

Website | |

Phone NO. | 0086-15092212967 |

Skype | mary.bonshin |

Tel number | 86-0532-85841183 |

.jpg)