製品情報

| 条件: 新しい | 原産地: ネザーランド | 銘柄: Dofra Foodtec |

| モデル番号: OP-120 | タイプ: カッター | 電圧: 220V - 380V |

| 力(W): 3,5KW | 重量: 1000 kg | 次元(L*W*H): 650 x 110 x 260 |

| 保証: 1 year | 提供される売り上げ後のサービス: 利用できる海外サービスセンター |

包装

| 包装: Standard packing of the onion peeler is in an open wooden skit. Other methods of packing is possible upon request. |

Onion peeler

Type OP-120

The uniqueness of this product lays in theapplication of a technology that is completely new. Because of the applicationof this new technology machines can be build and maintained easier with lesscomponents, are more hygienic because of less components that are easieraccessible, are more sustainable since permanent super magnets do not wear andrun without friction and the technology is used to replac components that dowear (springs, belts, moving components).

John deGroot, CEO of Dofra Foodtec

“We realized that if we wanted to offerour clients a good solution to the inconveniences of today’s machines, we hadto look at machine engineering from a complete different perspective. Avoidsprings that can break, avoid me-tal arms that can tear, avoid belts that canstretch, avoid friction that causes wear, reduce the number of components toincrease hygiene and make maintenance easier.

Quite a challenge. But we have realizedhuge improvement on all these issues via the application of a technology usingsuper magnetism. It took us three years of dedicated research and developmentwhich was subsidized by the European unio. Theresults are impressive.”

Technology

Dofra hasdeveloped and applied a technique using permanent super magnets. Using thistechnology Dofra is able to position, rotate, clamp and release onions in amachine environment, based on the physical position of the onion in themachine. Frictionless!!

The machineis equipped with various kinds of super magnets which were researched by Dofrafor a period of three years under subsidy of the European community.

The relatedtechnology of applied super magnetism in food processing machinery is patentedworldwide by Dofra.

Quality

In the same workspace as before,productivity is increased by 50% as the capacity of the machine increased by50% due to the applied super magnets.

The super magnets that are applied in the onion holders have been constructedin such manner that big onions do not get crushed and smaller onions do not getlost, without leaving deep (holding) marks in the onion.

The onionthat leaves the Magnetic Driven onion peeler has an identical quality as a handpeeled onion.

For qualityaspects on maintenance and hygiene see Productivity.

Productivity

The MagneticDriven peeling wheel works with 6 onion holders compared to 4 onion holders inconventional onion peelers, increasing the peeling capacity with 50%.

The MagneticDriven peeling wheel moves with more onion holders at a lower rotational speed.This results in a better control of the onion peeling process with up to astunning 90% reduction of onions that are lost during the peeling due tocentrifugal forces in the conventional peeling process.

Theconventional peeling wheel in an onion peeler consists of some 600 parts. The MagneticDriven peeling wheel consists of around 150 components. This greatly reducesthe complexity of maintenance and thus the costs of maintenance.

As the construction of the Magnetic Onionpeeling wheel is an open construction with rounded components and without theconventional springs and belts it is far more hygienic and easier and faster toclean.

Sustainability

Allcomponents that move and have friction, such as friction belts, springs, armsmoving on a curve disk, have wear and require periodical replacement, using upthe earth’s resources.

The permanentsuper magnets used by Dofra have a permanent magnetic field, with no loss ofstrength, no wear. The clamps are driven by magnets, opening and closing theclamps completely frictionless, thus no wear. The rotation of the onion in theonion clamp holder is done by magnets, without physical contact, thus completelyfrictionless with no wear.

If ever atechnology excels in sustainability, it is the super magnetism technologypatented worldwide by Dofra.

Singleinfeed-, dosing,- and singulating belt

- Infeedhopper with continuous moving back plate

- Continuousbelt with flexible transportationpins

- Turningwiper system to remove double laying onions

- Singulatordriven by the peeler

Capacity

Approximately 85-100 onions per minute. The capacity is determined by the size of theonions, the capacity and experience of the operator and feed system to theonion peeler.

Product requirements

- Onions with a diameter of approx. 60mm-140 mm / 2 ½” – 5 ½”

- For best results, the diameter variation of the onions per operation run should not exceedapprox. 25 mm (1”)

- The onions should be of a reasonable quality, in general round shape and haveto be deleafed.

Technical data

The peeler iscompletely made in stainless steel 304, except motor drives bearings etc. andequipped with fully enclosed bearings.

Motor power

Topping andtailing: 1,5 KW

Drive of cupchain and peeling wheel: 1,5 KW

Centrifugalventilator: 0,5 KW

Voltagemotors (standard): 380 V-3 phase– 50 Hz / 60 Hz

Volume of air: approx. 1,2 m3/min.,6 bar (clean and dry air, no oil)

Weight: approx. 1000 kg

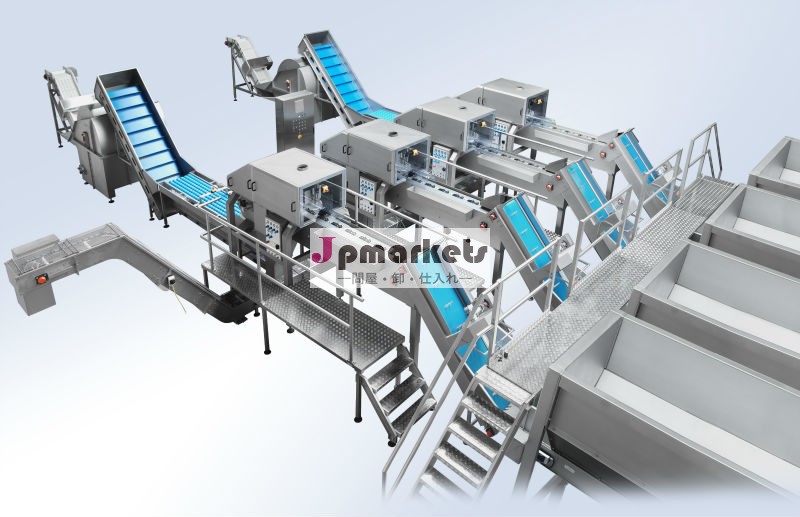

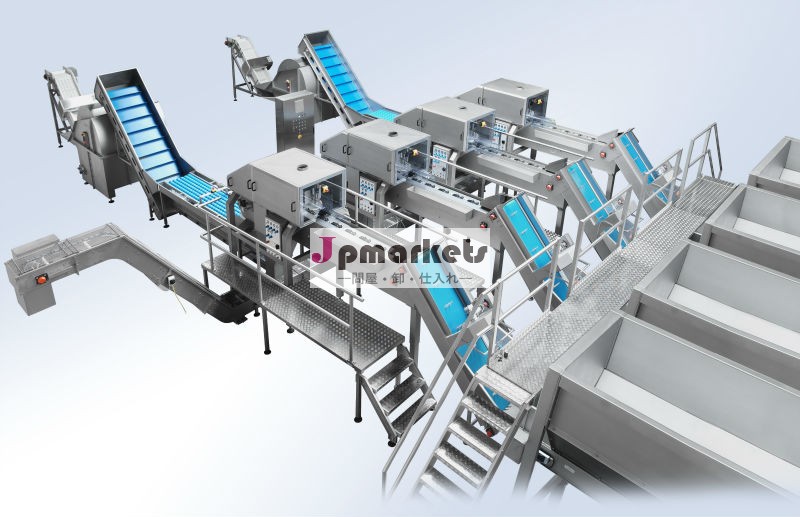

We also deliver complete processing lines for processing potatoes, onions, carrots, bell peppers, celeriac etc.