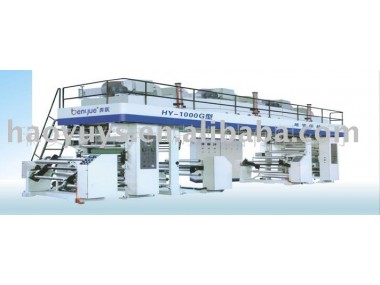

| 原産地: | 中国(本土) | 銘柄: | benyue | モデル番号: | Fh-zc |

包装

| 包装: | 木製ケース |

USAGE:

This FH-ZC high-speed dry laminating machine is developed the advance of JAPANESE FUJI standard, suitable for laminating rolled film two layers or multi-layers , such as BOPP, PET, nylon, CPP, CPE, and aluminum foils and other laminated materials in the packing industry.To produce high strength,fresh ,boilability pacage.

SEPCIFICATION:

type | FH-ZC1000 | FH-ZC800 |

roller width | 1050mm | 850mm |

laminating speed | 130m/min | 130m/min |

Machine speed | 160m/min | 160m/min |

DIA of Unwind | Φ600mm | Φ600mm |

DIA of rewind | Φ650mm | Φ650mm |

DIA of roll-core | Φ76mm | Φ76mm |

Heating power | 102kw | 90kw |

Total power | 120kw | 110kw |

Air pressure | 0.6mpa | 0.6mpa |

Water pressure | 0.2mpa | 0.2mpa |

weight | 14000kg | 11000kg |

Overall size | 118004450x400mm | 108004250x3900mm |

FUNCTION AND CHARACTERISTICS:

1.This machine is adopt PLC controller to ensure reliability.

2.Unwinding ,oven, rewinding, this four parts applied with fixed stable tension, which controlled and displayed by man-machine interface.

3.Drying system is adopts electronic heating. Oil furmace heating and steam heating transfer.

4.All guide roller keep same transmission, make material less tensile and deformation

5.There are two kinds of doctor blade type and pressing-type gluing ways can be chosen

6.Accuracy vein roller, erasing knife, glue distribute roller, glue recycle system.

7.Tri-roller accuracy composite equipment. Which adopts outer recycle oil-heating system to make equal hot degree.

8.Coating ,composite system adopts duplicate frequency motor, to ensure inner roller keep the same speed with printing procession

9.Pneumatic oven and trans-membrance controller worked with inner roller synchronous speed regulating.

10.The rewinding section adopts two AC motor to control taper tension, pneumatic press roll with automatic blade.

11. Every independent constant temperature section with heating are adopt recycle system and in-out air blower equipment

REQUIREMENT:

Manufacture machinery can according to request of the customers (width available 300-2000mm)

Heating method: Electricity heating, oil furnace heating,steam heating