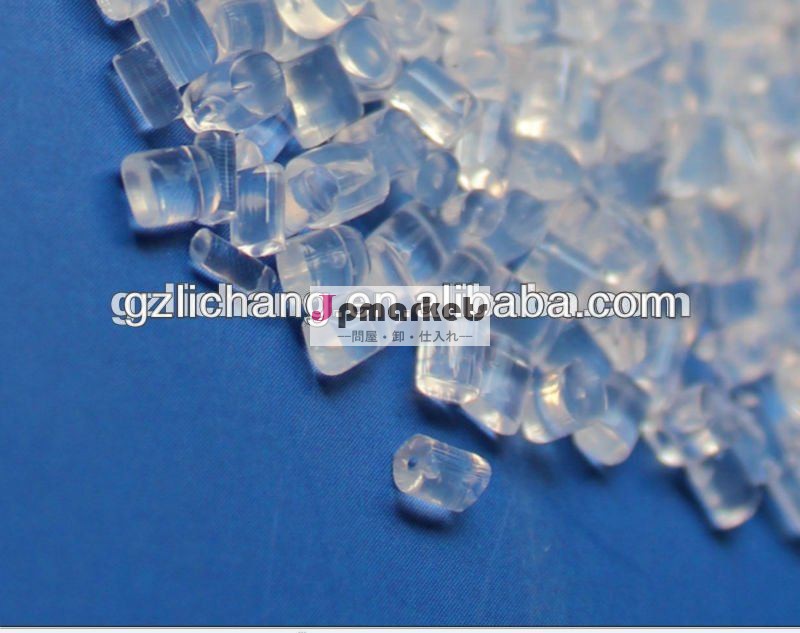

製品情報

| 原産地: 中国(本土) | 銘柄: lc | モデル番号: klc606 |

| 証明書: Iso9001: 2008 | タイプ: 合成樹脂やプラスチック | 色: アプリコット |

| mfr: G10/10分 | 材料: 複合高分子 | アプリケーション: インジェクション |

| 価格: 交渉可能 | パッケージ: カートン/pallet | moq: 25キログラム |

| 試験報告書: rohs指令 |

包装

| 包装: 25kgs/bag/カートン |

仕様

1)最も高温抵抗2)トップ耐薬品性3)放射線性4)直接メーカー5)hgih純度

Peek is a polyether products of amorphous aromatic、 whose trade name is polyether ether ketone。 this material's performance can meet the demands of harsh environment、 so it・rsquo; s a wide range of applications and practical kind plastic。 the wires、 which are made of this material、 have the following several excellent performance。

( a) high temperature

The presumption of the test: the continuous use temperature is 250 ・度; c、 and it can be achieved 315 ・度; cby the modified。、i ts melting point is 334 ・度; c、 and the temperature of extruder is near 380 ・度; c - 400 ・度; c。

( b) low- 密度

Peek whose density is only 1.4, compared to the other same level plastics which have high- 密度、 under the same weight、 this material can products produced more and the production of wire longer。

( c) of the radiation resistance

R radiation dose allowed in the table、 it is clear to the peek r- ray irradiation in the largest reduction in mechanical strength、 within the permitted range、 so the peek material is the most resistant to radiation。

Flame retardant and cigarettes of up to ul94v- o standard。

Chemical resistance and hydrolysis resistance、 it can prevent the erosion of organic and inorganic solvents。i nsoluble in conventional solvents、 ahd its have a great resistance to high pressure steam and hot water resistance。

peek・rsquo; s electrical properties is excellent、 and its dielectric constant、 dielectric loss、 breakdown voltage has more performance in a wide temperature and frequency range。

These are all excellent performance of peek、 because of its excellent performance、 the wires、 which is made of peek、 are widely used。

(a) replace the motor output line coating of ptfe thin tube、 ptfe thin tube is pushed way to get into technology、 many of the technology program、 inefficient、 resulting in high prices of thin tubes。 companies in foreign countries has been replaced with peek line。

(b) the mining、 oil and other harsh environment requires the wires which are resistance to acid、 alkali、 high temperature。

(c) the nuclear power plant、 the original understanding of power generation equipment and coated with a layer of wire、 the use of its flame、 heat、 radiation- 耐性、 easy molding、 and other characteristics of thin- 壁に囲まれた。

(d) the aircraft、 spacecraft、 the main advantage of using peek wire its low density、 resistance to radiation and other characteristics。

In short: as noted in the current knowledge、 peek wire is the best of all the wires。