| 電圧: | オーダーメイドする | 原産地: | 中国(本土) | 銘柄: | huihe |

条件: | 新しい | モデル番号: | 600-- 4000l | 重量: | 800kg | 力(W): | 9キロワット | タイプ: | オートクレープ | 保証: | 12ヶ月 | 認証: | ce | 次元(L*W*H): | 1500*900*1900mm | 使用法: | 酪農/缶詰食品/もパッケージ化された製品 | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | 材料: | ステンレス鋼 | 加熱タイプ: | Electric/蒸気加熱 | いずれかを入力: | 垂直/水平 | タイプ2: | アップ・ダウンダブルパン/平行ダブルパン |

包装

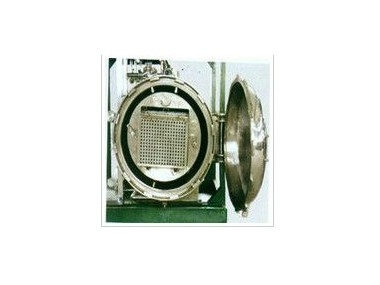

Rotary Retort are the equipments for canned food to cook, sterilize and cool. It is especially for the high rate of solid food (such as cans, rice pudding, milk peanuts, etc.) and other canned food which is various co

ncentrations and different viscosity. It can ensure not hierarchical and non-precipitation in the shelf time. In addition to the above characteristics, the material of this machine cage clamping device is used internatio

nally advanced pneumatic components; it has the advantages of reaso

nable design, compact structure, safe and reliable operation, high efficiency, with a simple installation, easy operation and maintenance, etc.

Usages

It can be used for food sterilization in glass bottles, plastic bottles, cooking bags, cans such as dairy products, beverage, canned food, rice pudding, ham, meat etc.

Characteristics

1. Co

nverting the direction of flow ensures uniform temperature and no dead ends 2. Fast heating, short sterilization short 3. High sterilization precision4. Automatic computer co

ntrol system a. The world’s most advanced Japan’s Mitsubishi Q-type PLC. b. 970 large touch screen. c. It can use the automatic temperature co

ntrol valve to adjust the temperature. d. The pressure transmitters can adopt electric display. e. It ca print and store the pressure curves of time, temperature and pressure. f. All the valve switches adopt computer control. g. Fully automated by computer programs without manual operation.5. Can be set to one type and multi stage sterilization 6. Function of measuring F7. Storage of sterilization formula

Technical Parameters

| Volume | 600L | 1100L | 1900L | 2200L | 3100L | 4000L |

| Body diameter (mm) | 800 | 900 | 1000 | 1100 | 1100 | 1200 |

| Body length (mm) | 1000 | 1500 | 2000 | 2000 | 3000 | 3000 |

| material | SUS304/ Q235-B |

| Designed pressure | 0.35MPa |

| Working pressure | <0.3MPa |

| Designed temperature | 140.7°C |

| Working pressure | <135°C |

Notes:1. The parameters in the chart are standard configurations. Any specific requirements, please put forward.2. The process parameters that need provided when choosing the retorts: the nature of material, sterilization process, specific requirements, etc.3. Accessories: storage gas tank, air compressor, water tank, boiler.

Technical Requirements

1. File support: the structural size drawing of the device (PDF) and instructions are available.2. Required by operated function, the following criteria are adopted to design, manufacture and testA. << Standards for quality co

ntrol of pharmaceutical production (Revised 1998)>> terms of Chapter IV 31-37;B. << The Steel Pressure Vessel (GB150-1998)>>;C. << The Steel Welding Normal Pressure Vessel (JB/T 4735-1997)>>;D. << Food Machinery Safety and Heath (GB 16798-1997)>>.