| 原産地: | 中国(本土) | 電圧: | 220ボルト/ 380ボルト/ 415ボルトまたはカスタマイズ | 適用: | 版 | 銘柄: | deerma | モデル番号: | SJSZ80/156 | 自動等級: | 全自動 | 重量: | 13トン | 力(W): | 180kw | 認証: | ce/iso9001: 2008/sgs | 処理されるプラスチック: | WPC | 提供される売り上げ後のサービス: | 利用できるエンジニア機械類を海外に整備するため | ねじ設計: | 二重ねじ | 条件: | 新しい | 次元(L*W*H): | 25*25*3メートル | プラスチック機: | wpc泡ボード機/ wpc泡ボード生産ライン価格 | 製品幅: | 1220ミリメートル/ 4フィート | 製品の厚さ: | 8〜18ミリメートル | 出力容量: | 300〜350キログラム/人事 | トラクター速度: | 0.8-1.5メートル/分 | 製品アプリケーション: | 家具、建物プレート、ハウス飾る電気ショック療法。 | 機制御: | plc-シーメンス | 機モーター: | シーメンス | インバータ: | abb | 保証時間: | 12ヶ月 |

包装

| 包装: | 1.モールドパッケージ: 木製のパッケージ。 2.外側のパッケージ: ストレッチフィルム3.積載数量: 2x40gp1生産のためのライン |

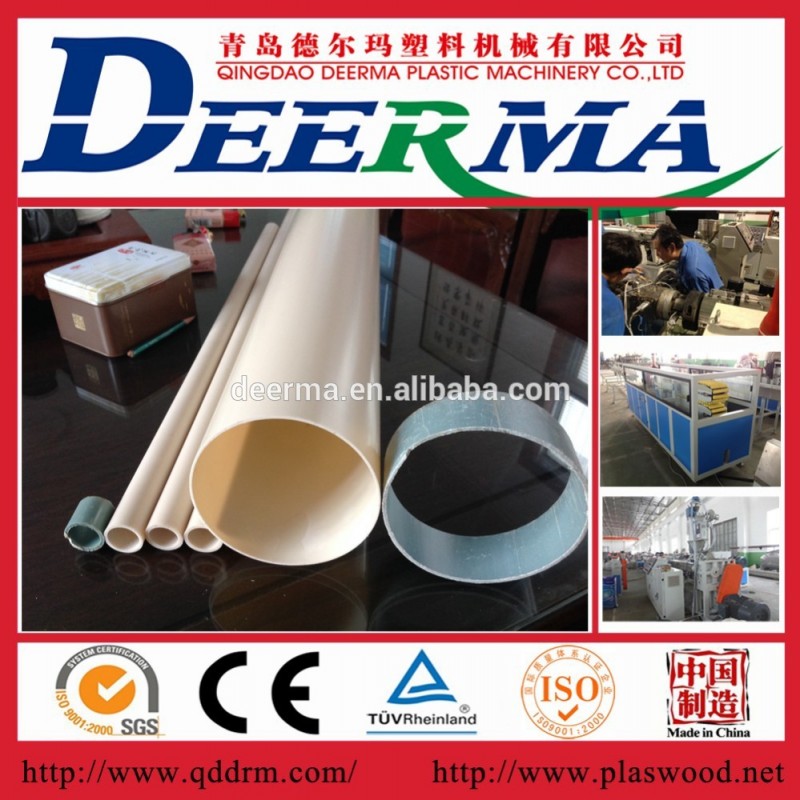

WPC Foam Board Machine / WPC Foam Board Production Line Price

Product Description

Qingdao Deerma WPC/PVC crust foam board machine includes twin-screw extruder , mold and other auxiliary machines , we use twin-screw extruder with compact structure. Superior performance. Besides the screw and barrel and die are designed by our company and made in world famous manufacturers.

Technical information & Machines List

Extruder | Width of WPC crust foam board | Thickness of WPC crust foam board | Output capacity |

SJSZ-80/156 Extruder | 1220mm | 9-18mm | 350Kg/h-400kg/h |

SJSZ-92/188 Extruder | 1830mm | 9-18mm | 800Kg/h-900kg/h |

Machine List for WPC PVC Foam Board Machine

- SJSZ80/156 Conical Double-screw Extruder

- Mould

- Calibration Forming Table

- Cooling Bracket

- Haul-off Unit

- Transverse Cutting Bracket

- Trim Cutting

- Stacker

DEERMA - Trade Assurance Limit : US $83,000

1.100% Product quality protection

If the product quality does not meet the standards set in your contract, Alibaba.com will refund the covered amount of your payment.

2.100% On-time shipment protection

If your products are not shipped on time as per your contract, Alibaba.com will refund the cover amount of your payment.

3.100& Payment protection

If the supplier breaks the on-time shipment or product quality terms of your contract, Alibaba.com will refund the covered amount of your payment

FAQ

1. Quality Control Management

Is there quality control on all production lines? | Yes, all production lines have adequate quality |

Do the QA/QC inspectors work independently from the production line? | Yes |

Who does the QC/QA Manager/Supervisor report to? | GM -- Mr. Yanzhong Li |

How many QA/QC inspectors in total? | 4 |

Number. of Employees in Each Production Line | Supervisor 1 No. of In-line QC/QA 2 |

2.Supplier Management

Does the company have a supplier assessment procedure? | Yes |

Does the company have an updated list of approved suppliers? | Yes |

Does the company establish and implement a standard procedure for purchasing contract review and approval? | Yes, with written standard procedures |

Does the company keep its supplier assessment reports? | Yes, assessment reports are available for the last 1-3 years |

Are the company’s purchasing documents sufficient to ensure product safety control and their customers’ requirements? | Yes, the purchasing document includes all the |

Is there a procedure to conduct random product inspections after final packaging? | Yes, with clear standard and written inspection records |

3.After Sales Service

Is customer feedback, including complaints, clearly recorded and | Yes, with a standard feedback form and records |

Are there any clear procedures for handling customer complaints? | Yes, with clear procedures and written records |

Is there a closed-loop corrective action system in place? | Yes |

Can finished/packaged products be traced by lot identification to the | Yes, with procedures to trace raw materials |

Is there a product alert and recall procedure? | No |

Our Services

Testing installation

1. We will do machine test-running at our workshop before delivery and we’ll invite you come to our company to testing the complete line with us together

2. After the machinery arrived at buyer’s factory, the seller should send technician to buyer’s company install and test the machinery .The buyer should pay the fee of air ticket , accommodation and the salary of technician USD 60 dollars per day .

Best Services

1.Our company will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience

2.After signing contract, company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers’ requirements and provides detail order list and matching manufacturer for reference for customer.

3.After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer’s locale in time when we provide service for client again.

We have six production lines in our showroom for other customer , welcome to visit our factory