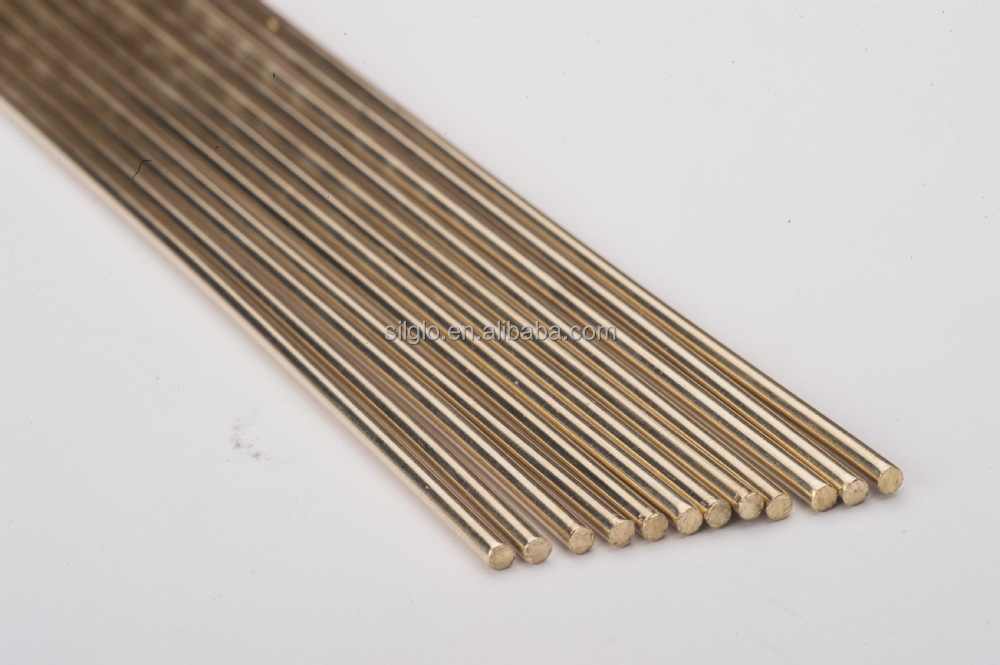

| 適用: | ろう付け溶接の銅、鋼と鋳鉄 | 原産地: | 中国(本土) | 銘柄: | グローバル | モデル番号: | hs221 | 実用温度: | 890-905 | 長さ: | 10〜1000ミリメートル | 材料: | 銅/銅合金 | 直径: | 0.8ミリメートル- 5.0ミリメートル | 組成: | cu. zn。sn。si | ソリダス: | 890 | liquidus: | 905 | ですか合金。: | は合金 |

包装

| 包装: | 各5kg+- 2%polybagで詰めの掃除機をかけ、 同封withdrier品質証明書。 20キログラム/カートン、 サイズ: 77*77*52cm |

Specifications

1.easy flow

2.low cost

3.shows perfect performance in contact brazing

4.good wettabitity

5.high strength

Copper-Zinc Brazing Alloys are suitable for gas-flame brazing ,high temperature brazing ,salt bath dip brazing of copper and copper alloys ,nickel, cast iron and hard alloys .While brazing by oxyacetylene, to heat with oxidized flame quickly can lessen evaporation of Zinc and prevent gas porosity due to over-oxidization. The optimum joint gap should be 0.025-0.1mm.Flux is also necessary for good seam.

Product Number | Chemical Composition | Melting Range(°C) | Application | |||||||

Cu | Zn | Sn | Fe | Ni | Si | Other | Solidus | Liquidus | ||

HS221 | 60 | Bal. | 1 | — | — | 0.3 | — | 890 | 905 | Melting point is about 900°C.Brazing welding of copper. Steel, and cast iron. |

RBCuZn-A | 59 | Bal. | 0.6 | — | — | — | — | 875 | 885 | Melting point is about 890°C.Brazing welding of copper. steel, and cast iron. |

RBCuZn-C | 58 | Bal. | 0.9 | 0.8 | — | 0.1 | — | 865 | 890 | Melting point is about 880°C.Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. |

RBCuZn-D | 48 | Bal. | — | — | 10 | 0.2 | — | 890 | 935 | Melting point is about 890°C and high strength. Braze welding of steel,nickel and carbide alloy, |

ERCuSn-A | Bal. | — | 6 | — | — | — | P:0.2 | 910 | 1040 | |

RBCuSn-C | Bal. | — | 7-9 | — | — | — | P:0.15-0.3 | 882 | 1027 | Good wear resistance.Argon arc welding of copper alloys and surfacing of steel. |

.jpg)