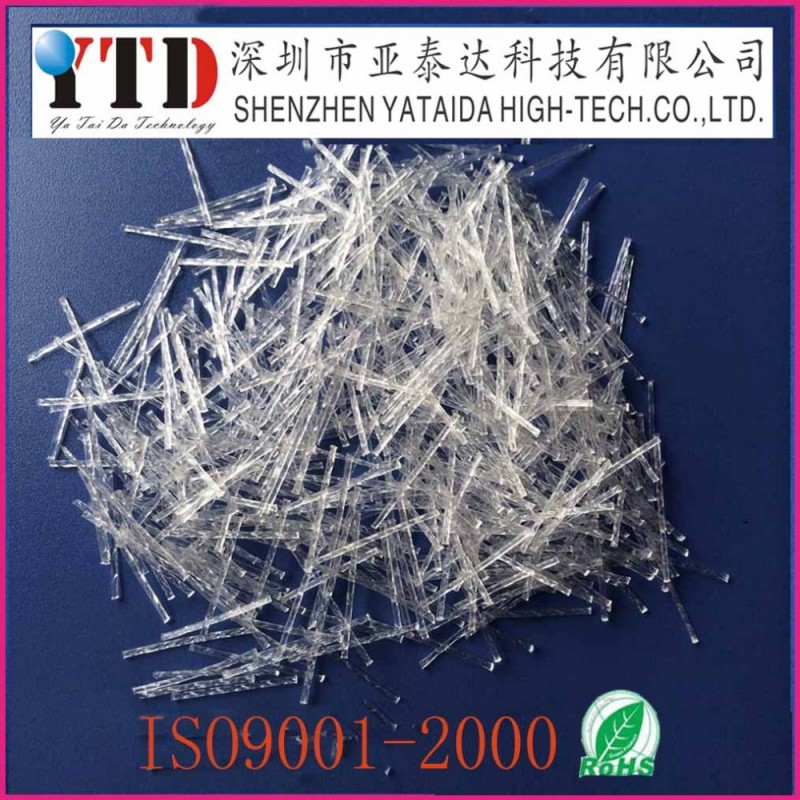

| パターン: | 未加工 | 原産地: | 中国(本土) | 銘柄: | 年初来 | モデル番号: | Pan-13-12 | 優良さ: | 13 | 特徴: | 化学薬品抵抗力がある | 材料: | アクリル系100% | 光沢: | 明るい | ファイバーの長さ: | 5〜25ミリメートル |

包装

| 包装: | 袋 |

Polyacrylonitrile fiber, also known as acrylic fiber or PAN fiber, it has higher elastic modulus,tensile strength and anti-UV properties,anti-high temperature and cold performance than polypropylene fiber, As cement concrete and asphalt concrete ribs, it can significantly increase the concrete tensile strength, anti-fatigue strength and anti-flexural strength, significantly improving the crack resistance of concrete at early age. Used in the asphalt significantly improve asphalt adhesion, high temperature stability, fatigue durability and low temperature cracking and to prevent reflection cracks, effectively improve the tensile, shear, compressive and impact strength. The true role and prospects for the use of polyacrylonitrile fibers in concrete has been the engineering sector awareness and acceptance

Range of applications

Applied to cement concrete

1, Precast concrete panels, components and other cement products

2, cement concrete road,pavement, bridge decks, airport runways

3, ports, deep-water pier, bridge, and cold regions engineering

4, the road crash retaining wall, impact baffles

5, reservoirs, swimming pools, corruption pool, sewage treatment pond

6, water conservancy and hydropower project in CFRD

7,Waterproofing of the basement side wall, floor, roof, roof slab and other structural

8, injection, pumping concrete

Used in asphalt concrete

1, the new asphalt pavement surface

2, Old Asphalt Pavement Overlay

3, pavement repair

4, the pavement cold patch, pouring

5, steel bridge deck pavement

The main function

For cement concrete:

1, effictively Improve thecapacity of cement concrete anti-cracking

(1) Good adhesion with the cement, to play a supporting role in the aggregate, to reduce bleeding and prevent subsidence cracks.

(2) adjusting the water content, to avoid rapid water evaporation caused by shrinkage cracks.

(3) adjustment temperature stress due to hydration heat inside the concrete and the external temperature change. reduce the crack level.

2, improve the impermeability and frost resistance of cement concrete to increase the durability of fiber, greatly reducing the number of scale and connectivity of the concrete pores, improve the frost resistance and impermeability of the cement concrete.

3, Reduce the brittleness of concrete,so the cracked concrete's strength was protected

4,To improve concrete's wear ability, tensile strength and toughness

5,Improve the impact resistance of concrete, resistance of earthquake, anti-cracking ability

6,Greatly improve the ability of the frost resistance of concrete, improve durability

For asphalt concrete:

1,improve the dispersion of asphalt concrete mixed materials

2, ribs role play in the asphalt mixture

3, increasing the oil content of the asphalt mixture, to enhance the bonding strength and stability

4, Improve the toughness of the asphalt mixture and the ability of anti-cold temperature.

5,Reduce permanent deformation to improve the slip resistant ability

6,Reduce the impact of temperature on the asphalt pavement, improve the water stability of the asphalt pavement

Performance parameters

Material composition | 100% polyacrylonitrile |

Specific Gravity(g/cm3) | 1.18 |

Elastic Modulus(GPa) | 7.1~16.3 |

Tensile strength (MPa) | 600-998 |

Elongation at break (%) | 15~25 |

Length (mm) | 6~25 (OEM) |

Equivalent diameter (μm) | >10 |

Material Shape | Boundle of monofilament |

Melting point ( °C ) | >230 |

Chemical properties | Resistance of acid,alkali |

Recommended dosage and construction technology

For cement concrete,generally add 0.6 to 0.9 kg / m 3,for higher impact deck pavement,the dosage can be as 1.5 to 1.8 kg / m 3. Generally 6mm in length for mortar,and 10 to 20mm length for concrete.

The role of fiber in concrete is achieved through the physical effects,there isn't any chemical reaction with concrete admixtures, cement.and no special requirements for the mixing equipments and construction technology.as follows:

According to the mixing amount of the polyacrylonitrile fiber,add proper quatity of sand,stone,cement, first dry mixed for 30 seconds use blender,then wet mix 1 minute with water,the construction and maintenace for the concrete with polyacrylonitrile fiber is same as it without polyacrylonitrile fiber.

Note: because of the addition of polyacrylonitrile fiber, the adhesion of concrete reinforced,however slump fell slightly, it is recommended to change the quantity of admixture but must not be by increasing the amount of water to adjust.

For asphalt concrete

1,when day and night car traffic volume <3000,1-1.5 kg polyacrylonitrile fiber per metric ton.

2,when day and night car traffic volume between 3000 and 8000 ,2-2. Kg polyacrylonitrile fiber per metric ton

3, when day and night car traffic volume > 8000 3-3.5 kg polyacrylonitrile fiber per metric ton

For bridge deck pavement

1,wearing surface 3.5 kg polyacrylonitrile fiber per metric ton

2,gas layer 2.5 kg polyacrylonitrile fiber per metric ton

polyacrylonitrile fiber together with the aggregate first dry more than 20 seconds,then injected into the asphalt for wet mix,total mixing time not less than 60 seconds,contruction technology is same as it without polyacrylonirtile fiber.but need more about 3 to 4 times of RCC. requirements of the actual degree of 98% or more

.jpg)